Our Autonomous Mobile Robots for the Electronics Sector – Open Shuttle

The production of circuit boards and electronics is highly organized and characterized by a high degree of automation. Electronics companies are also pioneers of digitalization. To gain ground in production efficiency, the links between the individual production steps and the optimal use of resources need to be perfected. Our Open Shuttles – automated guided vehicles (AGVs) for the electronics sector – organize transport processes flexibly and efficiently. They are autonomous mobile robots (AMRs) that are ideal for jumpstarting your automation.

Looking for flexible AMRs for the electronics sector?

Find out more about the Open Shuttle by KNAPP!

Our AMR models for the electronics sector

Our Open Shuttles are ideal for transport in the electronics industry. We offer two models you can select to meet your requirements:

Open Shuttle

AMR with roller conveyor load-handling device

for transporting magazines

Can secure payload through integrated width adjustment

Max. payload 50 kg (110 lb)

Open Shuttle

AMR with telescoping load-handling device

for transporting magazines

Connects directly to towers and machines

Max. payload 25 kg (55 lb)

Check out our high-tech AMRs for the electronics sector!

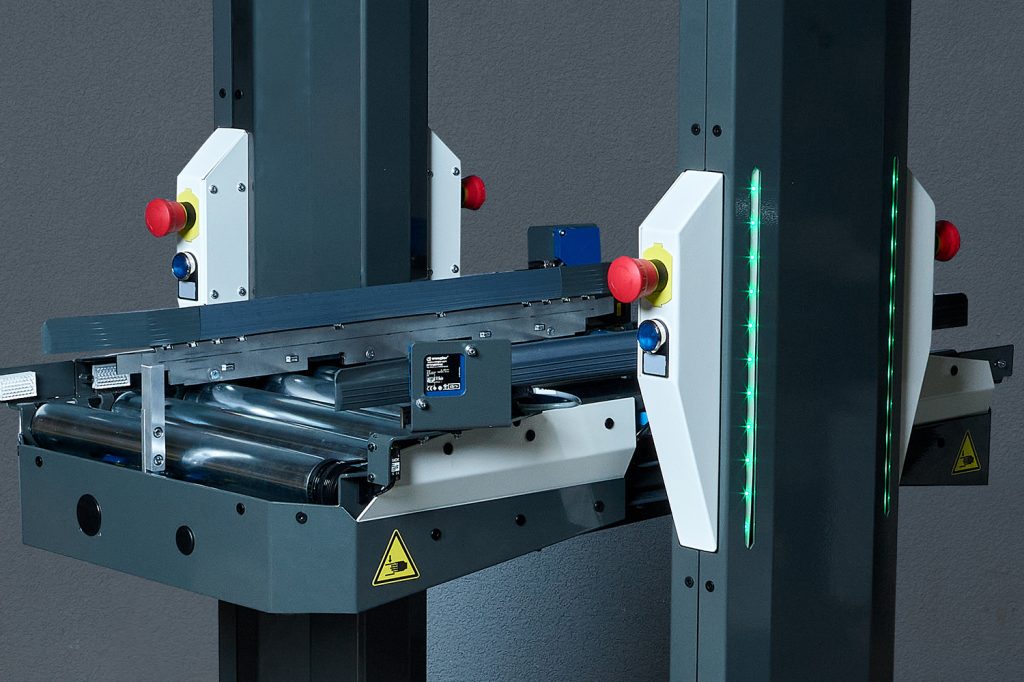

Autonomous mobile robots with special load-handling devices

In the electronics sector, load carriers such as circuit board magazines, reels, containers and tray stacks must be transported efficiently to production lines and automatic assembly machines. To support these processes, we developed a special load-handling device (LHD) for the Open Shuttles.

We designed them with integrated width adjustment, allowing the robots not only to transport magazines and containers of different widths, but also to center them as required. Magazines are secured in place during transport to prevent tipping. While moving, the LHD automatically adjusts to the dimensions of the load carrier for the next order, using time efficiently.

How do KNAPP’s autonomous mobile robots work?

Find out more about our intelligent Fleet Management Software!

Our AMRs feel at home in the electronics sector

Open Shuttles are highly versatile and the AMR fleet can be installed without any structural modifications, making Open Shuttles an ideal solution for retrofitting existing automated or manual systems with cutting-edge robotics.

Uses for AMRs in the electronics sector:

- Supplying work stations, setup locations and production lines

- Connecting production machines

- Connection to automatic storage systems, such as the ASM Material Tower

- Connection to pick-and-place machines

- Special and express transport tasks

Our Open Shuttles open up novel opportunities for interconnected transport in the warehouse. They are flexible and can be used in a number of settings, making them the perfect solution for handling peak periods.

Advantages of the Open Shuttle AMRs in the electronics sector

Easy to configure

Simple simulation and control of the layout, processes and fleet; changes can be made independently

Mixed fleets

Flexible interconnection of all warehouse areas with different warehouse vehicles in one system

Easy to integrate, quick startup

Works well with existing systems, no construction needed; quick and easy startup

Intelligent resource management

Smart path planning and intelligent coordination of orders and transport resources

Cost-efficient system

Increased efficiency thanks to 24/7 availability and consistent performance

Ready for immediate use in all industries

Autonomous, robust, deterministic navigation

Maximum safety

3D obstacle detection, blue light and signal lights for more safety in the warehouse, CE-certified

Global service network and a reliable partner

KNAPP as a reliable partner with global customer service

100+ successfully implemented customer projects

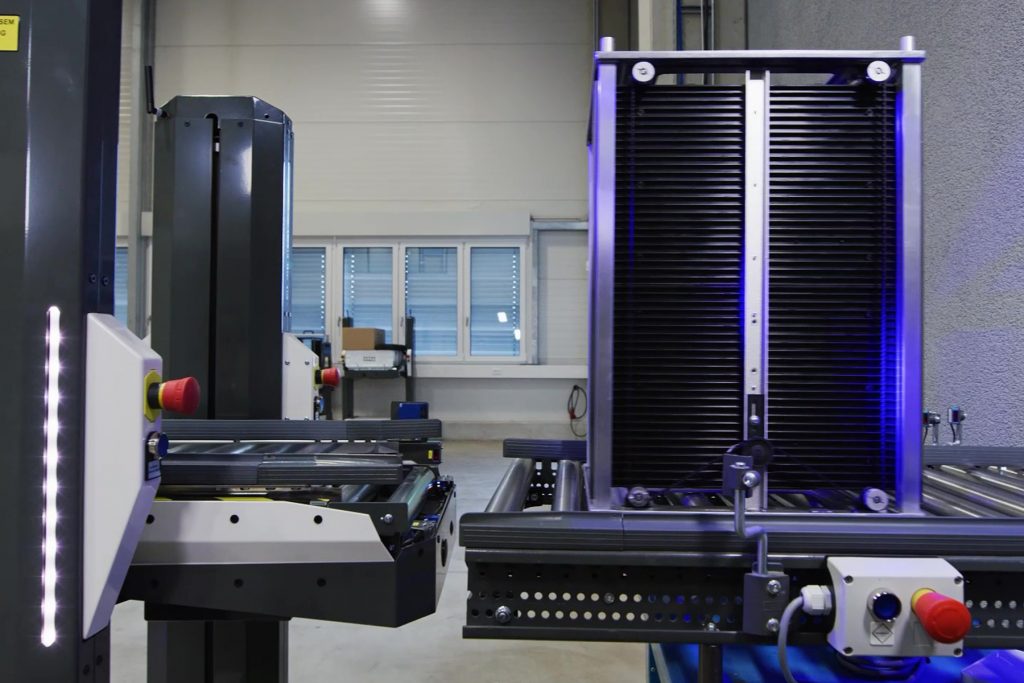

Open Shuttle + cassette + ASM Material Tower

= the perfect solution called Robot Batch Unit by ASM

Our certified Open Shuttle model for the ASM Material Tower storage system has a special load-handling device exclusively designed for the internal transport of cassettes. The ASM Material Tower fills cassettes with component reels according to the needs of the production lines. These reels contain tiny parts, which are built into the circuit boards by efficient, automated pick-and-place machines. To prevent interruption in production, the reel cassettes must be provided just-in-time to the pick-and-place machines. This important task is carried out by our Open Shuttles.

Find out how ASM uses our Open Shuttle AGVs!