The challenges in the food retail sector are manifold: Consumers’ shopping behavior is constantly changing while the range of items, pack unit types and sizes is growing. Aspects such as the physical strain on employees carrying out manual picking and labor shortages cannot be underestimated either. And, against a backdrop of increasing quality, efficiency and performance requirements for store delivery, each store has different order quantities and order frequencies.

Our new RUNPICK system, short for Robotic Universal Picker, provides solutions for the following challenges:

Automated systems for store-friendly delivery

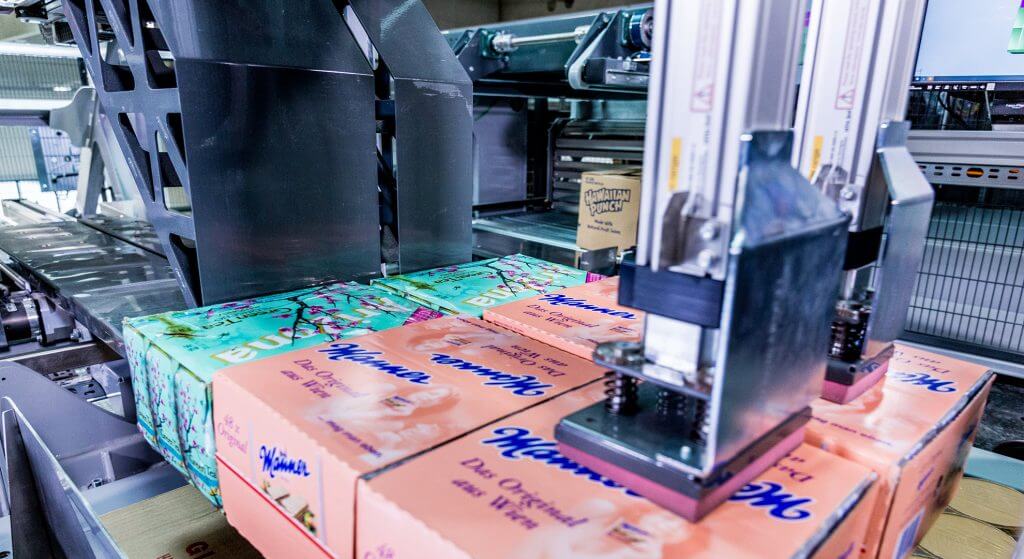

RUNPICK is a system specially designed for the food retail sector. It processes the entire range of groceries fully automatically. The robot picks and palletizes large handling units of fast-, medium- and slow-moving fresh and shelf-stable goods. RUNPICK builds mixed pallets and roll containers and is well-suited for supplying stores with different structures.

Higher performance thanks to multiple picks

With RUNPICK, we are setting new standards in store delivery. The robot’s major advantage over existing systems is its substantially increased performance: The system handles a variety of packaging types and processes them using multiple-item picking. Within a single cycle of movement, the robot moves and deposits several items at the same time, thereby increasing performance. The key to building mixed layers on the load carrier is to combine the items in a smart way.

The groups of items for multiple-item picking can comprise the same handling units or different unit types. RUNPICK is able to place several handling units on the target load carrier at the same time.

Store-specific picking

The stores receiving the goods differ in size, location and layout. So that employees can fill the shelves in as little time as possible, the following criteria play a decisive role in the automatic processing of groceries:

- Store-friendly delivery

- Customer-specific sequence of items

- Packing parameters

RUNPICK meets all of this with its intelligent packing algorithm, selectable picking criteria, and its ability to pack different types of pack units. This way, the system creates order pallets that are perfectly tailored to each store.

Smart combination of technologies for food retail

The software and interplay of all components are key in this solution. Our central OSR Shuttle™ Evo storage and picking system stores the handling units and retrieves them in the ideal sequence. The optimal stacking pattern is already calculated beforehand to ensure that the items are conveyed to the robot in the right sequence for stacking. Thanks to KiSoft Pack Master, our software for calculating packing parameters, RUNPICK knows exactly where to place each item on the pallet or in the roll container – in the perfect sequence for each store. Thanks to the optimal density, stability and composition of the order pallets, food retailers save time and costs.

The scalable and modular system adapts its performance flexibly to future growth and market demands.

Take a look at how our KiSoft Pack Master works:

The first RUNPICK system to start up in summer 2021

The first distribution center to include our RUNPICK solution will be put in operation in the US this summer. For test purposes, we installed a complete system – the same one we are building for our customer in the US – in Leoben, Austria. The system in Leoben is up and running. Technically speaking, we are testing the original to find potential for optimization in advance and be prepared for startup in the best possible way.

RUNPICK at a glance:

Integration in omni-channel models and solutions for store delivery

Solutions including RUNPICK are always comprised of a combination of our OSR Shuttle™ Evo, the KiSoft Pack Master and the picking and palletizing system. RUNPICK can ideally be integrated in conventional solutions for delivery to stores as well as in omni-channel models.

Omni-channel fulfillment and seamless commerce

Our new fully automatic concept, the omni-channel solution, links all sales channels, connecting all logistical processes within a warehouse: It is ideal for e-commerce and brick and mortar food retail as well as for a combination of both. Our omni-channel solutions play a vital role in networks that are composed of several distribution centers: This includes the supply of urban MFCs (Micro Fulfillment Centers), of brick and mortar stores and central e-commerce fulfillment using CFCs (Central Fulfillment Centers). Seamless commerce is more than just a buzzword.

Seamless commerce combines the best of both worlds: the convenience of online shopping with the fun experience of browsing around the shops. What’s more, it brings an entirely new level of service. Gather information, reserve a product online and pick it up in a nearby store. While waiting at the checkout counter has become a thing of the past, the concept of a store is retained as an important element in the customer journey.

Regardless of the segment requiring higher performance, our solution can flexibly respond to changing order volumes. Despite the difference in packaging, only one central warehouse system is required with the OSR Shuttle™ Evo. This way, synergies can be used to the optimum, which saves space and costs. The degree of automation can be adapted precisely to the customer’s wishes. Our intelligent robots come into play in the fully automatic version: The Pick-it-Easy Robot is used for online retail to fully automatically process single items while RUNPICK ensures optimal processes for store delivery.

The solution’s advantages:

- All logistics processes are handled in a single warehouse

- One solution for all sales channels

- Entire range located in one warehouse

- Picking of single items, small pack units and standardized large handling units

- Cost-effective and space-saving

- Use of synergies: deployment of technologies for a range of different applications

Fully automatic store delivery

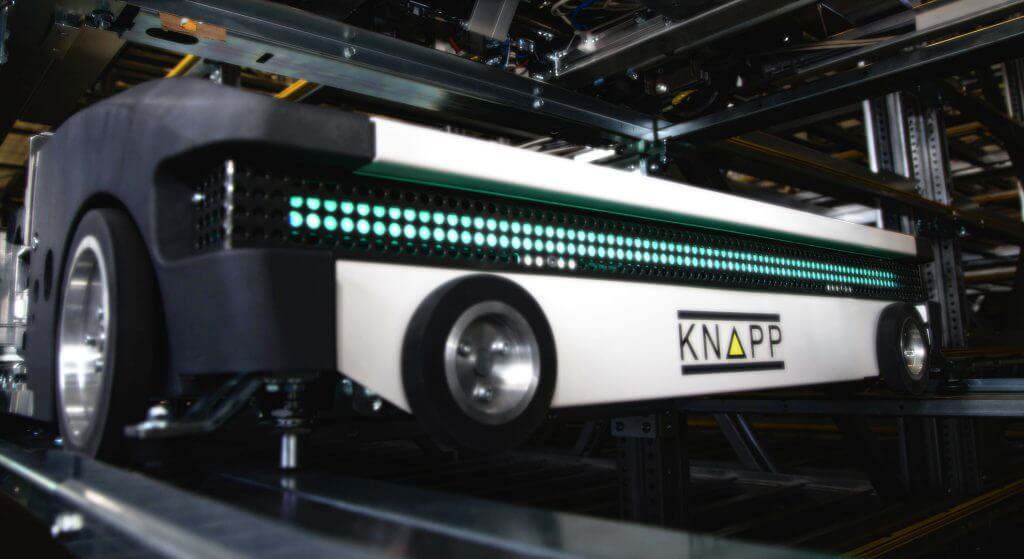

Of course, we also offer concepts designed for deliveries to stores exclusively. These solutions are fully automated with the help of RUNPICK. Our Flexible Case Picking system solution, for instance, allows responding to sector-specific fluctuations at all times and in a flexible manner. In the fully automatic version, the OSR Shuttle™ Evo, KiSoft Pack Master and RUNPICK again form the perfect team for the job. Included in the solution are autonomous robots, our Open Shuttles, which ensure flexible pallet transportation by moving around the warehouse freely without any aids.

Further reading recommendations

Intelligente Technologien für Omnichannel-Lösungen schaffen hier die Klammer zwischen online und offline. Dies erfüllt Kundenbedürfnisse und steigert die Wirtschaftlichkeit.

Robots are already supporting workers in countless logistics areas. In the food retail sector, it’s KNAPP’s Pick-it-Easy Robot who is playing a pivotal role in meticulously processing the diverse range of articles.

How can articles arrive at the customer undamaged? What can software do to reduce transport costs? How do the stock clerks in the stores benefit? What does KNAPP’s software KiSoft Pack Master have in common with Tetris? Here, the answers to these questions.

Additional Information

For more information on RUNPICK or our solutions, please contact us at ksi.sales@knapp.com.