Most of us have already ordered garments, shoes or accessories online. Maybe you have even selected a specific colour or material to suit your personal style. I’ll even bet that your new favourite pieces arrived at your home on the next day or perhaps you picked up your parcel at a location of your choosing. Does this all sound familiar? Years ago, this sounded like pie in the sky but today, it’s the new normal.

Over the past few decades, e-commerce has introduced tremendous and far-reaching changes to many sectors, but especially to the fashion sector. The changing market, technical advances and, let’s not forget, the comfort and convenience it provides the end customer are all leading the way into the future.

Customized products are desired as fast and as flexibly as possible: Same-day and next-day delivery as well as Click&Collect are highly popular for fashion shopping. Intuitive online shops, online advice and the seamless connection of sales channels are already a permanent feature of the shopping experience for fashionistas.

The fashion sector is definitely the front-runner when it comes to the development of online trade. In Germany, for example, market shares rose in the past ten years from about 6 % to about 27 %, with the prognosis for 2025 as high as up to 33 % [1].

New challenges demand new solutions

What does the rise in online trade mean for logistics? One huge challenge is expanding or building warehouses and distribution centres to handle the logistics demanded by the increasing online sales and growing article ranges. The additional demand for employees is also a particularly challenging aspect.

Efficient, customized automation

Problems such as the lack of resources are solved by using robotics in the supply chain, which simultaneously increases quality and profitability. Technological advances in robotics and artificial intelligence are transforming the world of logistics, promising innovative logistics processes. In logistics, robots already play a central role and are an integral part of warehouse automation.

Humans and machine do not compete with each other – they complement each other. A robot can carry out monotonous tasks for long periods with the same high quality. By comparison, a human can respond quickly and flexibly to new requirements. In shift operation that calls for a constant throughput and a low error rate, automation is the right choice. This is why humans and technology make a great team for implementing logistics requirements in the best way possible.

Theoretically, many processes in a warehouse can be automated using robotics. At KNAPP, we don’t ask ourselves “What can be automated?”, but “Which processes will be made safer, more productive and more efficient by using robots?” and “How can robots improve the human working environment?”

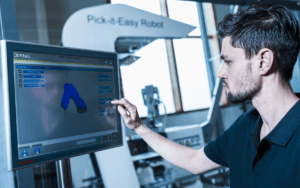

The intelligent robotic solution for the fashion sector: Pick-it-Easy Robot

In the fashion sector, robots are ideal for single-item picking and filling sorter pockets within dynamic buffer storage solutions. In comparison to other sectors, the difficulties in the fashion area lie in the many types of different products and packaging characteristics. This includes products with reflective or transparent surfaces such as window-box packaging or polybags with very flexible products in different sizes, everything from pocket handkerchiefs to shirts and thick pullovers.

Daniel Hierzer, Systems Engineer, Business Unit Fashion, KNAPP AG

At KNAPP, we have dedicated ourselves to artificial intelligence and robotics for many years to come up with the optimal solution for these challenges: The Pick-it-Easy Robot, our fully-automatic picking robot. Thanks to the intelligent Vision system for object recognition and grip point identification, the robot continuously learns how and where to grip new articles, thereby increasing the system performance. With the help of machine learning, Pick-it-Easy Robot knows how to best pick up the article, automatically selecting the right gripper, the ideal grip point and the right speed for picking the article.

Thanks to machine learning, the intelligence of the Pick-it-Easy Robot increases with each article

The Pick-it-Easy Robot learns with every new product, every recalculated grip point and every gripping process. The collective experiences can therefore be used to constantly enhance the performance of the system and to continually broaden the range of articles.

Our robotics solution for the fashion sector: Pick-it-Easy Robot

As a result, the Pick-it-Easy Robot can handle the wide article range in the fashion sector with ultimate reliability and can guarantee high availability around the clock.

Integration is key

To use a robot cell in the most optimal way, it must be integrated into the overall process. Here, experience is key and at KNAPP we draw upon a considerable number of successfully implemented solutions. However, what makes KNAPP truly successful is not only experience, but also designing the optimal solution for each individual customer. We view ourselves as partners who are involved throughout the whole process. We evaluate the articles for robot suitability and do the designing, planning, implementation and startup of the robot cell, topping it off with after sales support.

Daniel Hierzer, Systems Engineer, Business Unit Fashion, KNAPP AG

Our experts in robotics and machine learning are continually developing the Pick-it-Easy Robot, working with our customers to shape the future. We are therefore well-equipped for the many challenges that the fashion sector has in store for us.

[1] GfK GeoMarketing and statista.com

Further reading recommendations

In what ways can robotics and AI be used in retail logistics? How can robots help on Black Friday? How do robots take the pressure off humans in the warehouse?

Intelligent pocket sorter solutions bring order into every warehouse – whether in fashion, retail or e-commerce. The pocket sorter achieves order from chaos with speed, efficiency and surprising flexibility.

Machine learning is everywhere. But what exactly lies behind this future technology? Is it really possible to teach machines to learn? What advantages does it offer– and where does KNAPP come into play? Let’s take a closer look.