Today, we are a leading technological company with locations on every inhabited continent. How did it all begin? No one would suspect its humble beginnings.

I was born on October 9, 1907 in Marburg, Slovenia. I studied mechanical engineering at the University of Technology in Graz, Austria. In 1930, I acquired a trade licence for haulage and delivered goods with my own truck throughout Styria. In December of the same year, I began working at the Styrian Electricity Company as an electrical engineering technician. In 1952, I established a small workshop in the basement of my home in Graz. In December, I founded a sole proprietorship with two employees.

The development of the first machines

Günter Knapp initially worked on his own developments. His first two employees were fitters by trade and in the first year, he worked with them on the development of oil burners that would suit the requirements for Austrian oil. Most of the oil burners used at the time came from the US and were therefore better suited to the consistency of American heating oil. Austrian heating oil, by contrast, had a thicker viscosity, which is why Günter Knapp built an oil burner with larger atomizing nozzles. The pre-heated oil was sucked with air through special pumps, forming an emulsion that could be easily atomized under low pressure. Günter Knapp obtained his first patent for this product.

Along with oil burners, the company also built oil tanks and oil pumps, for example, to heat a Steweag power plant near Frohnleiten. Günter Knapp and his employees also provided service and repair work for various types of machines, such as those used in bakeries or central heating systems.

Entering the conveyor system business

In 1960, Günter Knapp was looking for a larger location, which he found in the Waltendorf district in Graz. The new premises comprised a 12 x 12 metre hall and an office. There, he developed the first autopicker, designed for the easier and faster retrieval of pharmaceutical items from wholesale warehouses. However, Günter Knapp was ahead of his times, which is why the apothecary committee to whom he introduced the 2 meter long autopicker was not impressed by this innovation. Nevertheless, Günter Knapp did not give up. The company began to build paternosters, goods lifts, lifting systems and belt conveyors. These systems were already equipped with mechanical-electrical or electro-magnetic control systems.

One of the first customers was the pharmacuetical wholesaler Herba in Graz. The two companies are still working together to this day.

In recent years, all Austrian Heba locations were modernized and expended with innovative KNAPP technologies.

KNAPP built goods lifts and conveyor belts for Stiefelkönig, the Sorger bakery and the car battery manufacturer Bosch.

For Kastner & Öhler, Günter Knapp built a large paternoster that connected the stockroom in the basement with all the floors. Even back then, customer service played an important role. In the meantime, repairing and servicing machines and heating systems provided enough work for seven employees in the growing company.

Thanks to KNAPP’s great reputation in plant engineering for the pharmaceutical companies Herba and Chemosan, the company received its first order from abroad in 1972. The German pharmaceutical wholesaler Dr. Krey & Vigener signed a contract for the installation of a conveyor system and a double paternoster in Düsseldorf and Krefeld. The German pharmaceutical market was booming and the first conveyor systems proved to be outstanding reference projects. Orders from other pharmaceutical wholesalers across Germany soon followed.

Research and development in focus

Günter Knapp recognized the necessity of specialization, which is why he placed great value on research and development. Since the rapid delivery of items in pharmaceutical wholesale became even more important, electronics was expected to provide much needed improvements. The first successful installation of computers took place as early as in 1978. Microprocessor units in the individual stations of the conveyor system were now controlling the flow of containers in which the requested items were placed at the individual picking stations. This was the foundation for the precise control of container diversion as well as rapid order processing.

Our company back then, KNAPP-Fördertechnik, was flourishing, mainly thanks to orders coming in from abroad. The export of high quality technology at the time was also a key factor in our success. Between 1973 and 1980, the number of employees increased from 15 to 74. In 1979, Günter Knapp opened the first company cafeteria for his employees.

The age of modern intralogistics

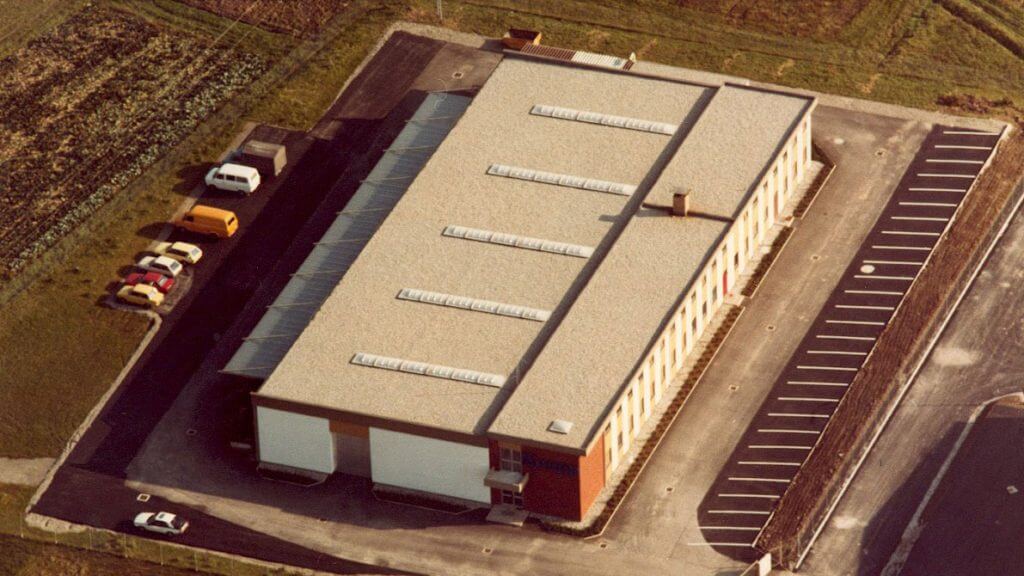

The 1980s were marked by strong growth. The company focussed on the development of the first computer-controlled conveyor and picking systems. The cornerstone was laid for the headquarters in Hart bei Graz.

- Automated picking: In the late 1970s, the company shifted their focus to the development of an automatic picking machine for simplifying order fulfilment in large pharmaceutical warehouses. Shortly after changing company locations, the first autopicker was introduced to the market. What made this autopicker stand out was its microprocessors at the channel ejectors for ejecting the requested items onto a conveyor belt, which in turn then transferred the items into a container at the end of the conveyor.

- Conveyor technology: The conveyor technology of the time was all about improving the electronics. As sales in Germany were flourishing, the company’s focus shifted increasingly towards the entire European market. Exports gained in importance, while the importance of the Austrian market kept declining. By the end of the 1980s, KNAPP already had an export quota of 90 % with about 100 employees.

Reorganization became necessary at the end of the 1980s because of the numerous large orders. The Electronics department was split into the Hardware, Software and Development departments. The employees responsible for plant construction became project managers with increased responsibilities. In addition to Italy, France, Belgium and the Netherlands, KNAPP entered new markets such as Scandinavia, Spain, Portugal and South America. The autopicker was adapted to other sectors such as textiles, cosmetics and books.

The idea was to expand the existing product range and to reduce dependency on the pharmaceutical sector.

Innovation and Expansion

Starting in the 1990s, expansion and certain innovations led the way for the KNAPP group’s inclusion in the World’s Top-20 Material Handling Supplier. In 1989, KNAPP entered the US market. With the acquisition of the companies Logim and Syslog, we strengthened our software competencies. In 2001, the plant area was doubled at the Graz location and, a year later, we were already employing more than 1,000 employees.

The founding of KNAPP AG

KNAPP AG was founded in 2007, which is responsible for the strategic direction of the company. With this development, we prepared ourselves for continued dynamic growth. At the beginning of 2008, the company decided to build the new Corporate Headquarters and Development Centre at the Hart bei Graz location. With the acquisition of the Scandinavian logistics company MOVING, today KNAPP AB, we now had locations in Sweden, Denmark and Norway. Development work focussed on a batch-oriented warehouse management system that significantly influenced distribution solutions.

Even in 2009, a year marked by economic crisis, we were able to win further market shares. While the overall market declined significantly, the promising markets of Latin American and Eastern Europe were booming. We established subsidiaries in South Africa and Switzerland.

Dürkopp Fördertechnik joins the KNAPP Group

In July 2010, we took a major expansion step: We acquired Dürkopp Fördertechnik GmbH. The acquisition was a strategically important expansion in terms of expertise as it meant integrating key technologies for the fashion sector in the company.

In addition to the highest order receipt and turnover in company history, the year 2010 was marked by outstanding performances. AVON in Brazil put the largest distribution centre for cosmetics into operation and Hermes Fulfilment installed the world’s largest OSR Shuttle™ for handling the returns for Otto-Versand.

- In 2013, YLOG Industry Solutions (today: KNAPP Industry Solutions) was founded. With a particularly flexible shuttle system, we expanded our sector focus to include the areas industry and production.

- In 2014, we acquired shares of the KHT Apostore Group. KHT is specialist in measurement devices and data input, Apostore in automating pharmacies.

- With further innovations in the technologies for shuttles, work stations and customized service, we entered a new era in automation. These developments led to the founding of two more innovative companies within the KNAPP group: ivii GmbH, specialist in image recognition and redPILOT, with a software of the same name for optimizing warehouse operation.

Strong growth until today

KNAPP has grown tremendously since its establishment and has 5,000 employees worldwide. In addition to a new office building and halls at the company headquarters in Hart bei Graz, in the past year the locations in Leoben and Dobl were expanded and, just recently, a new headquarters in the US was opened.

Further reading recommendations

As innovators, the continual development of our products is essential. This is how we remain strong and reliable partners for our customers worldwide.

Dürkopp Fördertechnik has been part of the KNAPP group since 2010. Thanks to this merger, we’ve got a first class collaboration providing expertise and industry know-how from a single source. Johannes Holas and Sigurd Völker reminisce about the past 10 years.

Come and follow some of our colleagues through a typical working day and gain exciting insights into the history and company culture of KNAPP and into the world of logistics.

Additional Information

Sources: Graz Trade Licensing Office, diploma thesis on the historical development and the business activities of Ing. Günter Knapp GesmbH & Co. KG