When logistics software plays Tetris

How can a system be sure to make the right decisions in an automated warehousing environment? Someone must think through all the possible alternatives and point in the right direction. For our automation solutions, these functions are handled by the KiSoft software portfolio. There is a lot to keep in mind when assembling orders but in the end, all the articles must arrive undamaged at their intended location and the effort required there should be as low as possible. This is where the packing arrangement calculation software KiSoft Pack Master steps in: The software solution functions as the brain for the picking process.

Next level: Shop-friendly delivery

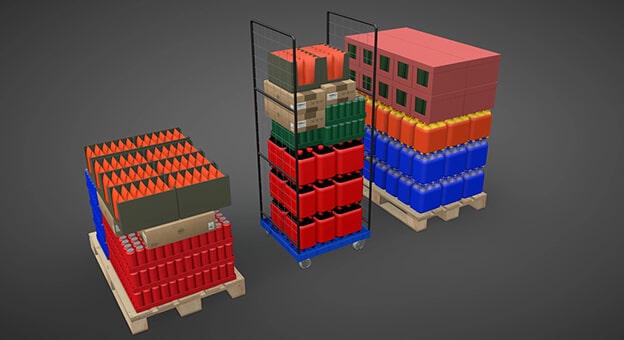

The principle is easy to explain: KiSoft Pack Master plays a round of Tetris during picking. When an order starts, the software is already considering the optimal position for the entire order on the target load unit. That’s how all the building blocks – that is to say the cartons, large pack units or single items – land in the optimal positions and end up forming a stable and space-saving unit. The software always keeps in mind that some merchandise categories are either kept together or kept separated. In this way, load units come together characterized by optimal stability and filled to the maximum level. KiSoft Pack Master doesn’t just consider load unit reduction and stability: The software also aims to make the job of the stock clerk in the store as easy as possible. Thanks to proper grouping and arrangement, the articles are in reverse sequence on the load units, ideal for replenishing the shelves in the stores.

Consistent quality and error-free processes

How do automated storage systems like the OSR Shuttle™ Evo decide in what sequence to retrieve articles for picking? And how do employees and robots arrange articles for stability while saving as much space as possible? During pre-calculation, the software considers special article-properties such as the packaging shape, dimensions, weight, load-bearing capacity and surface texture. By doing so, the software is able to find the perfect position for every article on the load carrier and can then retrieve the articles in precisely the right sequence. The system then supplies the goods for picking in the correct sequence. KiSoft Pack Master can be used with semi and fully-automatic solutions; with the help of visual displays, warehouse workers can stack goods on the load carriers in the optimal arrangement and robots automatically receive the correct commands. As a result, everything ends up in the right place. Constant quality and error-free processes are guaranteed and the articles arrive undamaged at the customer.

KNAPP stands for constant innovation and never hesitates to forge new paths. Our packing arrangement calculation software KiSoft Pack Master also stands for innovation: Not only can the software be used in all sectors, it also always considers the entire order in its calculation. This means it makes significantly more complex calculations, which provides the customer with tremendous advantage.

Unpack your advantages by packing with KiSoft Pack Master

- Shop-friendly delivery thanks to shop-friendly grouping of the pack units

- Optimal fill level thanks to the best possible packing density on the load carrier

- Stability from ideally balanced weight and height

- Continuous picking performance by calculating the packing patterns for each order

- Straight-forward man-machine dialogue thanks to the user-friendly display of information according to the easyUse operating concept

- Lower transport costs with fewer load units

Further reading recommendations

Invisible. Essential. Underestimated. Software. Software – it’s invisible, essential and yet all too often completely underestimated. Though we are mostly unaware of it, software accompanies…

Machine learning is everywhere. But what exactly lies behind this future technology? Is it really possible to teach machines to learn? What advantages does it offer– and where does KNAPP come into play? Let’s take a closer look.

When combined with the autonomous vehicles, the Open Shuttles, the OSR Shuttle™ Evo becomes the intelligent and flexible system solution, the OSR Shuttle™ Evo+.

Additional Information

Would you like to assemble your orders in a way that saves you time and space? Find out more about our software solution, KiSoft Pack Master, at ksi.sales@knapp.com.