The jewelry and watch industry is an exciting field uniting precision, craftmanship and innovation. Behind the shimmering luxury goods and technological masterpieces lies a hidden but complex world of stock management and production. Manufacturers have extremely rigorous requirements for the intralogistics they need.

Find out in this blog how our technologies meet the special features and challenges in the luxury goods industry, and what a practical example of an automation solution for this industry would look like.

Table of contents

The challenge: Diligent care and security in production and storage

The production of watches and jewelry requires meticulous care. Every step in the manufacturing, processing and mounting of the finished luxury goods demands the highest precision. This diligence is also needed in managing the stock and in transporting the components and finished products within the facility.

Given the large number of parts required to manufacture a watch or a piece of jewelry, efficient warehousing is absolutely essential for running the production processes smoothly. Furthermore, the finished goods must be stored safely and securely to prevent damage and be able to deliver the desired level of quality.

What makes a good storage system for luxury goods

A specially adapted storage system is critical for fulfilling the requirements of this sector, and it must be able to provide the following:

Warehouse automation optimizes quality and efficiency

An automated solution for stock management and internal transport is therefore the obvious choice to meet the requirements of the sector and to ensure process reliability and the highest quality standards. Implementing automation technology has the following benefits:

For companies in the jewelry and watch industry, using an automated storage system is tremendously significant. They remain competitive over the long term, lower their costs and sustainably keep and continue to develop high standards for quality, not only for their products but also in their internal logistics.

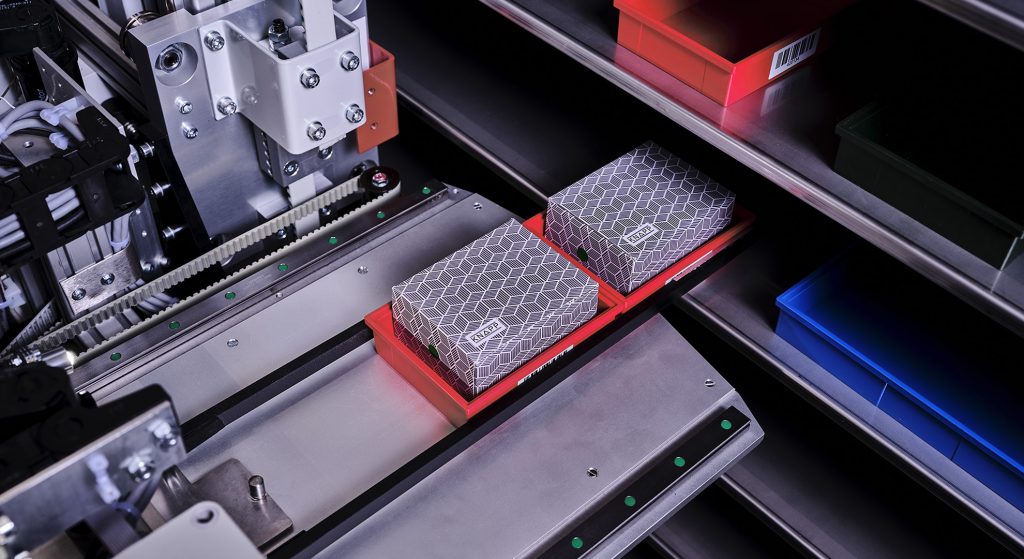

InduStore – the perfect technology for the jewelry and watch industry

Our automated small parts warehouse, the InduStore, is the ultimate automation solution for managing the stock of jewelry and watches. InduStore offers secure, space-effective storage of single items and (very) small load carriers. The system routinely handles single items, containers, trays and cartons up to 5 kg (11 lbs) in weight. With a picking performance of up to 500 items per hour, the InduStore is perfect not only as a production supply warehouse, but also as a warehouse for shipping, buffering and spare parts.

Smart system delivers perfect small parts storage and retrieval

All items in stock are recorded and documented in detail in the software. The goods are tracked 100 %, so there are no mixups or incorrect retrievals. Thanks to scanning on all six sides, the products are automatically identified. The self-learning software also continuously optimizes the use of storage locations. Inventory, normally a time-consuming process, can be done at the push of a button with the InduStore.

Being in the jewelry business, it was important for us to have a system that stores items completely theft-proof. The InduStore is designed to do just that.

A flexible system with many smart combination options

The automated small parts warehouse is flexible and can be extended at any time. For changes in the range of goods or seasonal fluctuations, shelves can simply be added or removed to adapt the storage space. Furthermore, the InduStore integrates well with other technologies for the fully automated provision of production work stations:

Example: Optimal automation solution for manufacturing luxury goods

We show you what an automated intralogistics solution might look like based on an example for a manufacturer of luxury items.

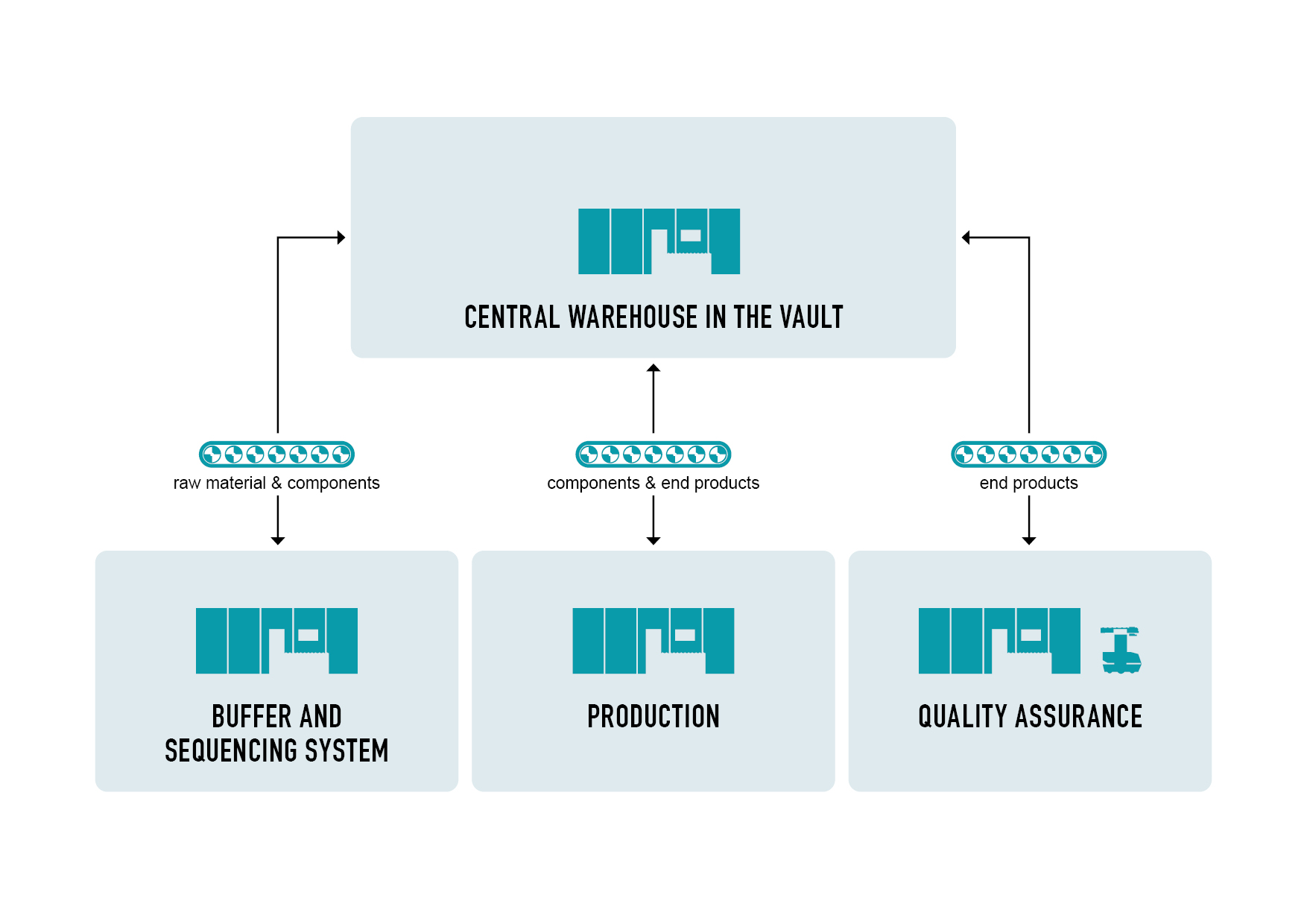

Several automated small parts warehouses, the InduStores, form the heart of the luxury-item producer’s automation solution. They are completely integrated into the building, in which the central warehouse is located in a separate vault. The new storage system supports four basic processes for the manufacturer. It offers central storage, provides buffering and sequencing, supplies the production work stations and is involved in quality assurance:

1) Central warehouse

The central warehouse is the hub for the production processes. Here, raw materials, components and finished products are stored and goods are supplied for order preparation, production and quality assurance. The central warehouse is also connected to the receiving and shipping areas.

2) Buffer and sequencing system

InduStore functions as a buffer and sequencing system for order preparation. The raw materials are requested from the central warehouse, temporarily stored in the InduStore and supplied in a strict sequence to personnel for order preparation. Once a work order is completed, it is stored in the InduStore before being transported back to the central warehouse.

3) Production supply

The work order is then delivered from the central warehouse to the InduStore in production. The components for the production order are fully automatically supplied to the employees. After the assembly of the luxury item, the completed product is temporarily stored and then sent to the central warehouse.

4) Quality check

All the final products undergo a quality check. For this process, they are automatically transported from the central warehouse to quality control. The final luxury items are temporarily stored and automatically sent to the individual check stations. Once the quality check is completed successfully, the end products are sent back to the central warehouse from the InduStore before being retrieved for shipping.

1) Central warehouse

The central warehouse is the hub for the production processes. Here, raw materials, components and finished products are stored and goods are supplied for order preparation, production and quality assurance. The central warehouse is also connected to the receiving and shipping areas.

2) Buffer and sequencing system

InduStore functions as a buffer and sequencing system for order preparation. The raw materials are requested from the central warehouse, temporarily stored in the InduStore and supplied in a strict sequence to personnel for order preparation. Once a work order is completed, it is stored in the InduStore before being transported back to the central warehouse.

3) Production supply

The work order is then delivered from the central warehouse to the InduStore in production. The components for the production order are fully automatically supplied to the employees. After the assembly of the luxury item, the completed product is temporarily stored and then sent to the central warehouse.

4) Quality check

All the final products undergo a quality check. For this process, they are automatically transported from the central warehouse to quality control. The final luxury items are temporarily stored and automatically sent to the individual check stations. Once the quality check is completed successfully, the end products are sent back to the central warehouse from the InduStore before being retrieved for shipping.

The following graphic illustrates how material flows in the manufacturing processes of a luxury goods manufacturer:

Automated connection and digital integration

Streamline conveyors are the central connecting element between the central warehouse and the receiving, shipping and production areas, as well as order preparation and quality assurance. For quality assurance, the Open Shuttles are used for transporting the end products to the check stations, taking the finished luxury items from the quality assurance InduStore to and from the respective check station. In the background, KNAPP’s KiSoft One software interfaces with the customers Host system providing smooth-running processes. KiSoft Analytics and KiSoft SCADA ensure that the customer always has an overview of all the processes.

The solution at a glance

• InduStore as a buffer and sequencing system for order preparation

• InduStore for production supply

• InduStore as a warehouse for the quality assurance process

Advantages of the automation solution

Conclusion: Efficiency and increased quality

Automation in the storage systems in the jewelry and watch industry leads to more efficient and more secure stock management along with faster order processing with simultaneous reduction in errors. Quality in jewelry and watch manufacturing is ensured and the costs are reduced over the long term. Implementing automation solutions is necessary to remain competitive over the long term and to be able to meet the demands of the sector.

Further reading recommendations

Today’s logistical challenges require innovative solutions. Find out now how you can shape the future of your logistics with the help of robotics and AI.

Optimize intralogistics processes and increase performance using automation. What is the right degree of automation for your operation? In this post, we present various levels, from innovative manual warehouses up to fully automatic systems.

Flow meter manufacturer Digmesa automates production using an Open Shuttle. Learn more about the flexible solution in an interview with managing directors of the Digmesa Group.