The new EU Packaging and Packaging Waste Regulation has far-reaching implications for company logistics – from procurement and warehousing to transport and returns management. Logistics companies, manufacturers and retailers face the challenge of changing their packaging processes to comply with the new regulation. But what exactly does the PPWR mean for logistics? Find out here!

The most important requirements set by the PPWR for logistics

With the new Packaging and Packaging Waste Regulation (PPWR), the European Union has passed a groundbreaking regulation that fundamentally changes how companies manage packaging. The aims of the new regulation are to drastically reduce packaging waste along the entire value chain, to improve recyclability and to promote sustainable packaging solutions.. The regulation has set clear rules:

Timeline of the new EU Packaging and Packaging Waste Regulation (PPWR)

After the existing Packaging and Packaging Waste Directive was reviewed in 2024, the European Union introduced the new Packaging and Packaging Waste Regulation, which came into force on February 12, 2025. Most of the PPWR’s individual regulations come into force for all EU members on August 12, 2026. However, a transitional period extends through 2040 for several requirements.

Fines and penalties: Companies that violate the PPWR will face considerable fines.

Effects of the new EU Packaging and Packaging Waste Regulation

The new EU Packaging and Packaging Waste Regulation has far-reaching effects. Transport and distribution logistics – and the last mile in particular – are strongly affected because packaging plays a central role in these fields. Using standard-sized cartons for all products – and as a result shipping products in oversized cartons and/or with extra void fill – is no longer a viable strategy under the PPWR.

The new packaging requirements will also affect warehousing. Smaller and more efficient packaging means a higher packing density in racks and shipping containers, which can improve storage capacity while making more efficient use of the available space.

Size reduction:

Under the PPWR, pallet loads and shipping cartons must be adapted to the size of the product to minimize empty space and thus the amount of air transported. Intelligent automated packaging systems can help optimize package size and the amount of empty space – and save material, too.

Required space:

Since packaging sizes need to be reduced under the new EU Packaging and Packaging Waste Regulation, more products can be stored in the same space, creating opportunities for storage capacity to be used more efficiently.

Material limitations:

Plastic packaging that does not meet the minimum requirement of recycled material is no longer allowed under the PPWR. Void fill used for deliveries must also meet these standards and conventional plastic cushioning must be replaced by eco-friendly alternatives.

Reusable solutions:

The Packaging and Packaging Waste Regulation means that logistics companies will have to start utilizing more reusable pallets, crates and containers. Reusable packaging is more expensive to procure and has to be cleaned and inspected after each use.

Efficient storage strategies:

Increased use of reusable packaging that has to be returned and reused increases the complexity of warehouses. Getting transport containers ready for reuse as quickly as possible will be imperative.

New machines:

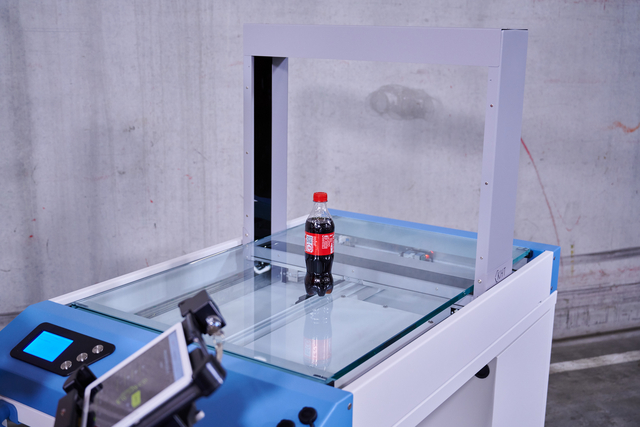

Packing machines have to be adapted to meet the new standards laid out in the EU Packaging and Packaging Waste Regulation. For example, they might need retooling to handle right-sized cartons or reusable packages.

More transparency:

In the future, companies will have to label products’ recyclability and material composition more clearly. Meeting these requirements demands efficient approaches and the right partners to help streamline the process.

Fulfilling the requirements of the EU Packaging and Packaging Waste Regulation

Companies should get their existing warehouses and warehouse concepts ready for the new requirements as soon as possible – and make any required adjustments sooner rather than later. The right partner can help fulfill the new requirements and allow the logistics system to benefit from custom, end-to-end solutions for the entire value chain. Additionally, the following measures can help companies comply with the EU Packaging and Packaging Waste Regulation in their daily operations. The effect of each individual measure can be amplified by embedding it in an efficient, complete logistics solution with software, helping you make the most of each action.

Right-size packaging:

Automated packing systems can help you comply with the Packaging and Packaging Waste Regulation by minimizing package sizes, therefore saving space and material. These systems automatically create custom packaging for each specific order tailor-fit to the size of its contents, reducing the amount of packaging material used and helping fill up the transport vehicle. When combined with an all-in-one automated logistics solution, the entire process can be done fully automatically.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDifferent carton sizes:

One alternative to right-size packaging is selecting different standard carton sizes. Data can be used to guide the picking process so that shipping cartons in the right standard size for each order are erected before the order is even picked. Orders are then picked directly into that carton. This solution also reduces empty space in the carton and saves materials, all in line with the EU Packaging and Packaging Waste Regulation.

Pallet packing density:

Palletizing and picking robots are an innovative solution for fully automatically assembling store-friendly pallets. The robots place pack units on pallets or in roll containers to optimize use of the available space, while their intelligent software calculates the perfect packing pattern at order start. Each robot uses this information to stack the goods in the correct order, resulting in a compact and secure stack, excellent packing density and maximum stability – and even reduced transport costs for companies. Automatic pallet assembly is especially valuable for the food retail sector.

Compostable or recyclable packaging:

Companies should switch to sustainable packaging early enough to meet the requirements of the PPWR. Paper-based or biodegradable materials are environmentally friendly replacements for plastic packaging. Filling material inside transport containers also has to meet these new requirements. Corrugated cardboard, for example, is excellent at keeping items transported in cartons secure. It’s not only lightweight and stable, but also completely recyclable and compostable, making it a green alternative to plastics.

Automated data collection:

When combined with the right software solution, machines can automatically record important master data such as item weight, size, stacking factors or item hierarchies and then automatically transmit this data to the WMS. Automating data collection reduces the amount of time and labor required for maintaining master data and ensures that goods can be handled efficiently in an automated all-in-one logistics solution. Companies can then automatically analyze the master data to make data-based decisions about the ideal storage location in a warehouse, the right shipping carton or the optimal way to assemble a pallet. This information helps companies operate in compliance with the EU Packaging and Packaging Waste Regulation, reduce empty space and avoid incorrect data. All in all, it works to make the warehouse more efficient.

Efficient reverse logistics:

Reusable containers must be ready to be shipped out again quickly. Implementing efficient returns processes allows companies to keep container procurement costs low and to lessen their environmental impact. Sophisticated, custom-designed warehouse layouts that support the company’s unique business case are at the heart of efficient reverse logistics.

The takeaway: The PPWR and new opportunities for sustainable logistics

While the new Packaging and Packaging Waste Regulation (PPWR) means companies are being faced with new challenges, it also presents an opportunity for them to do business more sustainably. Efficient packing solutions, reusables management systems and digital technologies hold the key to successfully meeting these new requirements.

Investing early in new logistics processes means much more than meeting legal requirements; it also provides an opportunity to save costs over the long term and to position yourself as an environmentally friendly company. Companies that deal with the EU Packaging and Packaging Waste Regulation today will be more competitive tomorrow – because sustainable logistics isn’t just a legal requirement, but a decisive factor for success.

New Dimensions of Knowledge

Today’s logistical challenges require innovative solutions. Find out now how you can shape the future of your logistics with the help of robotics and AI.

Further reading recommendations

In logistics, sustainability is an omnipresent topic. We would like to show you 4 good reasons why it makes sense to protect the environment, work efficiently and benefit from the many positive effects. Find out more!

The grocery industry is transforming its way into the future. Grocers using MFCs will be the ones getting it right first.