Are you pursuing an SAP® IT strategy and considering implementing SAP® EWM in the form of a warehouse management system (WMS) and warehouse control system (WCS)? If so, you have come to the right blog. Based on our 10-plus years of experience as SAP partner with a track record of over 110 SAP® EWM projects successfully implemented by KNAPP, we have compiled a list of 11 questions you absolutely should ask yourself when it comes to planning your own SAP® EWM project.

Table of Contents

1. Is SAP® EWM as both a warehouse management system (WMS) and warehouse control system (WCS) a good fit for my company?

If your business is pursuing an SAP® IT strategy, SAP® EWM (extended warehouse management) is generally the right choice. Although this might be obvious, warehouse management systems such as SAP® EWM are not plug and play systems. Choosing the right solution and especially the right time to implement it are important aspects to consider as these systems usually remain in place for decades. That’s why we at KNAPP provide solution concepts and fit-gap analyses as part of the WMS evaluation for SAP® EWM suitability.

The SAP® EWM solution concept includes:

The SAP® EWM fit-gap analysis includes:

In short

2. What do I generally have to consider when implementing SAP® EWM?

How the various aspects are evaluated in an SAP® EWM implementation project varies from case to case. Based on our experience, the following three topics should be given special attention:

The project team

Implementing a new warehouse management system does not just involve the in-house IT department. Mapping and optimizing the logistics processes also requires the know-how of the colleagues involved in logistics. That’s why members of both departments should be part of the internal project team, which is managed by a person in a clearly defined management role. This manager working for the customer monitors and supports the project, helps initiate any necessary decisions, acts as intermediary with the SAP partner, coordinates deadlines and designates qualified contact persons for certain areas and processes.

Focusing on what’s important

While defining the requirements for SAP® EWM, you might be tempted to add a long list of features and processes tailored to your business. However, if you opt for a standard product such as SAP® EWM, you should definitely evaluate in which cases the standard processes cover all your needs and in which cases modifications to the software are necessary. The fit-gap analysis mentioned above can help you with that. Alternatively, you can focus on the essential processes to ensure trouble-free daily business. These processes are established in the form of minimum viable products. All these form the basis for further subsequent optimizations.

The right SAP partner

An experienced SAP® EWM implementation partner is vital for a successful SAP® EWM implementation project. The right SAP partner not only is an expert in all things related to SAP® EWM, but also brings experience to the table, in particular in project management dealing with customer business processes and comparable warehouse automation. This is the only way to ensure that the solution optimally fulfills both the SAP® EWM standard and specific customer’s requirements. These include, among other things, industry, automation and a 24/7 Service Desk starting from day the system goes live.

In short

3. Which project approach is ideal for implementing SAP® EWM?

Many different approaches are available: classic, waterfall, SCRUM, Business Blueprint, SAP Activate, joint team, fixed price and agile contracts, depending on the work based on time and material. Even though there are a variety of project approaches, not every approach is suited to every company interested in SAP® EWM. Choose the right approach for your initial situation. This may sound obvious, but it’s not always that simple. In some cases, possible options need to be weighed against each other so that the right approach can be found.

4. How can SAP® EWM be deployed?

Using the latest SAP® ERP software solution, SAP® S/4HANA, SAP® EWM can be implemented as an on-premise or cloud solution. While on-premises installations run on servers owned by the customer, support for SAP cloud IT infrastructures is provided through a membership service. Within these two categories, SAP offers different options.

SAP® EWM as an on-premises solution

- Embedded EWM on SAP® S/4HANA shares a system with the central SAP® ERP system, which ensures smooth system integration. This option is tailored specifically to the needs of small to medium-sized warehouses and production warehouses. Depending on the requirements, customers can choose between Basic Warehouse Management and Extended Warehouse Management that comes with additional functions.

- Decentralized EWM on SAP® S/4HANA is a system installed on its own, separate from the ERP system. In the event of a system failure of or maintenance work on the ERP system, SAP® EWM can continue operating without a problem. Compared to Embedded EWM, the local version is easier to scale, making it better suited to map warehouse processes involving high volumes and high levels of intensity and automation.

SAP® EWM cloud solution

- SAP® S/4HANA Cloud, Private edition is suited for both local or embedded SAP® EWM implementation projects and has the same advantages as on-premises solutions. This allows you to customize and modify the SAP® EWM standard system, which is hosted on a private server and receives technical management and support from SAP. We shine some light on how to successfully migrate from on-premises SAP® EWM to SAP® EWM for S/4HANA Cloud, private edition in this blog post.

- SAP® EWM offers SAP® S/4HANA Cloud, Public edition within the SAP® S/4HANA Cloud, which is used by several SAP customers.

In short

5. Can I carry out an SAP® EWM implementation project in any number of warehouses?

Yes, you can, since SAP® EWM is a scalable software solution. As it is implemented in a template, an SAP® EWM implementation project can be successfully rolled out at multiple locations. Projects with four to five warehouse locations are typical in our experience, but there is no limit to the number of warehouses.

For example, we created an SAP® EWM template including a Pick-by-Voice system for a large retail company, which was then swiftly rolled out at about 50 locations across Europe. Currently, we are working on further templates and roll-out projects.

An SAP® EWM template is developed based on an in-depth analysis of the logistics processes and workflows for the relevant warehouse locations. It should be noted that a template in this context does not necessarily mean one size fits all. In this case, SAP® EWM is also adapted to the specific logistics processes of the customer and the relevant warehouse locations. Any state-of-the-art automation solutions are directly integrated as well. In addition to facilitating efficient SAP® EWM implementation at the current warehouse locations, SAP® EWM templates are also flexible and future-proof, enabling the customer to respond appropriately as the market changes and the network of warehouse locations expands.

In short

6. How long does an SAP® EWM implementation project take to complete and how much does it cost?

The duration and costs of an SAP® EWM implementation project depend on a variety of factors such as the system requirements, the complexity of the logistics processes, the necessary modifications to the standard software and the active involvement of the customer. A typical SAP® EWM implementation project for a complex RF-guided warehouse using automation lasts 1 to 2 years and requires a budget of 1 to 3 million euros from the project start to the acceptance by the customer.

Although the startup together with the acceptance marks the official end of an SAP® EWM implementation project, the project is not necessarily entirely completed. In the course of requests for change, i.e. subsequent requests for modifications and optimizations, the project often continues indirectly on a smaller scale.

In short

7. Is it a good idea to include the MFS module in an SAP® EWM implementation?

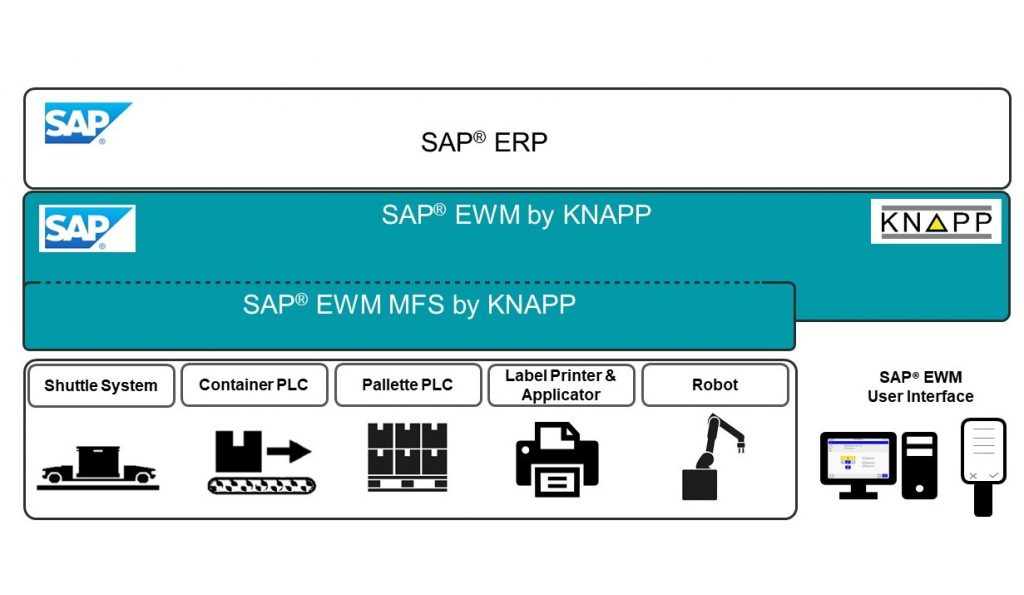

The module for the material flow system (MFS) is included in the standard SAP® EWM solution in the form of a WCS layer, but not in the SAP® EWM embedded basic solution. It is primarily designed to control the material flow in automated warehouses such as automated small parts warehouses and high-bay racking systems. However, it is also used in sophisticated, complex, highly automated logistics centers.

In the course of implementing SAP® EWM in automated warehouses, we recommend using MFS as an end-to-end SAP® solution. This way, the automated warehouse technology and conveyor system can directly be integrated into the PLC control system. As a result, fewer interfaces are needed, which increases process reliability overall. What’s more, the logistics processes are all mapped in an end-to-end SAP® system landscape.

In short

8. Is SAP® EWM implementation for a greenfield project any different from a brownfield project?

From a technical point of view, there are no differences between an SAP® EWM implementation project in a greenfield or an existing warehouse. What’s different, however, is the way these two project types are prepared and implemented.

In brownfield projects, old systems that have been in use for 20 years or more are replaced. This means there is a wealth of documentation available, which is vital for an SAP® EWM implementation project. That’s why we recommend reviewing these documents prior to project start to verify if interface adaptations, specifications on resolving error situations and subsequent changes to the implementation and operation phases – among other things – have been clearly and completely documented. Along with extensive documentation, old systems are usually highly optimized because of their long-time usage. Although it’s tempting to map these systems in SAP® EWM as they are, doing so is not very useful for understanding the requirements for the new system that are independent of the solution. An analysis with respect to future market and customer requirements should be conducted to identify which processes are already covered by the SAP® EWM standard solution and which might need to be adapted. The fit-gap analysis mentioned above helps to determine which processes fall under each category.

When implementing SAP® EWM for a greenfield project, there are no historic legacies to deal with. This is a great opportunity to tailor the new system from scratch to meet current requirements without having to compromise. But let’s not get carried away. Even for a greenfield project, you should focus on what matters most and plan the ramp-up phase properly and in detail so it can be completed in a timely fashion.

In short

9. How can I best prepare my employees for SAP® EWM?

Preparing employees from the IT and logistics departments for an SAP® EWM implementation project should include the following two elements: an initial briefing and training. Before a project starts, employees are often not sufficiently briefed on the new system implementation or change-over. However, providing a briefing is important for ensuring the employees accept the project. It is not enough to simply tell the relevant employees that SAP® EWM is going to be implemented; rather, you should go out of your way and clearly and concisely communicate the reasons, goals, expected advantages and potential disadvantages in individual areas in advance.

In addition to the basic training for SAP® EWM, which is provided by SAP, we at KNAPP offer additional training for selected key users. KNAPP’s training focuses on the customer-specific extensions of the SAP® EWM standard. In the course of the different project phases, key users are made familiar with the software and take on important tasks for the project such as creating test cases and training end users. Ultimately, they act as a help desk to ensure smooth operation of the system once it goes live.

KNAPP provided tip-top training to our SAP® in-house module managers, enabling them to independently maintain the modules in the future. Collaborating during the implementation not only helped us build up the necessary know-how, but also created trust in and acceptance of the new software as part of the essential change management. The relationship between the EGLO and the KNAPP teams has been characterized by a high level of partnership and mutual trust.

In order to gain all the necessary knowledge on how to manage SAP® EWM as independently as possible, many of our customers opt for a joint team approach. In this specific approach, the customer project team is actively involved in the implementation in order to gain knowledge. The first step of this approach involves naming suitable employees of the customer to fulfill the role of future SAP® EWM module managers or in-house SAP® EWM consultants. In addition to attending workshops and training sessions, they receive on-the-job training during the implementation phase by working with our project team. Once the project is completed, their responsibilities include creating specifications documents and functional specifications for SAP® EWM in the event of changes or extensions. They are also responsible for customizations, documentation, tests, putting the system into operation and training or assisting the key users in the different technical departments.

In short

10. Do I need any services around SAP® EWM after the go live?

The go-live date is the ultimate milestone of any SAP® EWM implementation project. At the time of the startup of the new WMS and WCS, it should be clear how the system will be managed from that moment on. At KNAPP, we usually advise our customers to evaluate at the latest three months prior to the scheduled go-live date whether or not they will be able to manage their system independently. If not, there should definitely be a support contract for the solution in place when the system goes live. One option is our 24/7 SAP® EWM Service Desk, which ensures fast and proper/expert support if errors occur.

In short

11. Can I selectively use SAP BTP so I don’t have to implement SAP® EWM?

No. SAP BTP, short for SAP Business Technology Platform, and SAP® EWM were designed for different purposes. SAP® EWM was developed especially for warehouse management and mapping complex logistical processes, while SAP BTP is a platform as a service (PaaS). This all-in-one development and deployment platform allows users to integrate different solutions for application development, automation, data analysis, integration and AI seamlessly into an existing SAP® process landscape using standard interfaces. The services implemented using SAP BTP can “only” be used to expand the functionality of SAP® EWM. At KNAPP, for example, we use SAP BTP to provide applications for varied logistics services and to integrate simple automation technologies, allowing AMR systems such as our Open Shuttles or automated picking systems such as InduStore to be implemented quickly, flexibly and at low risk.

In short

12. Do you have any specific questions about SAP® EWM?

We are happy to talk with you about your questions about an SAP® EWM implementation project. Feel free to reach out and arrange for a personal meeting where we can talk in detail about the specific challenges for your logistics operations. Together, we can find out how best to support you with an SAP® EWM or SAP BTP solution.

Further reading recommendations

Putting the regulations on serialization and rules into practice is a decisive factor in ensuring an efficient warehouse management system in the pharmaceutical sector. Find out in this blog post what smart functions and solutions SAP® EWM by KNAPP offers.

Are you in the health sector and relying on an SAP® IT strategy? With our Healthcare Model Company, we offer preconfigured, installation-ready and end-to-end software modules that broaden the SAP standard and are tailored to the special requirements of the healthcare sector.