The Comprehensive Pharma Value Chain at VOIGT

State-of-the-art infrastructure with stringent safety measures, minimal costs, availability of the entire product range within minutes and fast adaptability to new market situations – to help VOIGT overcome the challenges of the future value chain in the pharmaceutical sector, we’ve designed a handy solution together with VOIGT: VOLOGIN, a flexible logistics solution controlled by SAP® EWM by KNAPP.

Merging pre-wholesale and wholesale into one pharma value chain

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOriginally, we were looking for separate hardware and software suppliers. Since the two areas overlap, however, it made sense to have one supplier for both. The innovation we came up with together with KNAPP holds a range of possibilities and helps us support our customers with better tailored and very individual solutions in the future.

VOLOGIN: an innovative intralogistics concept

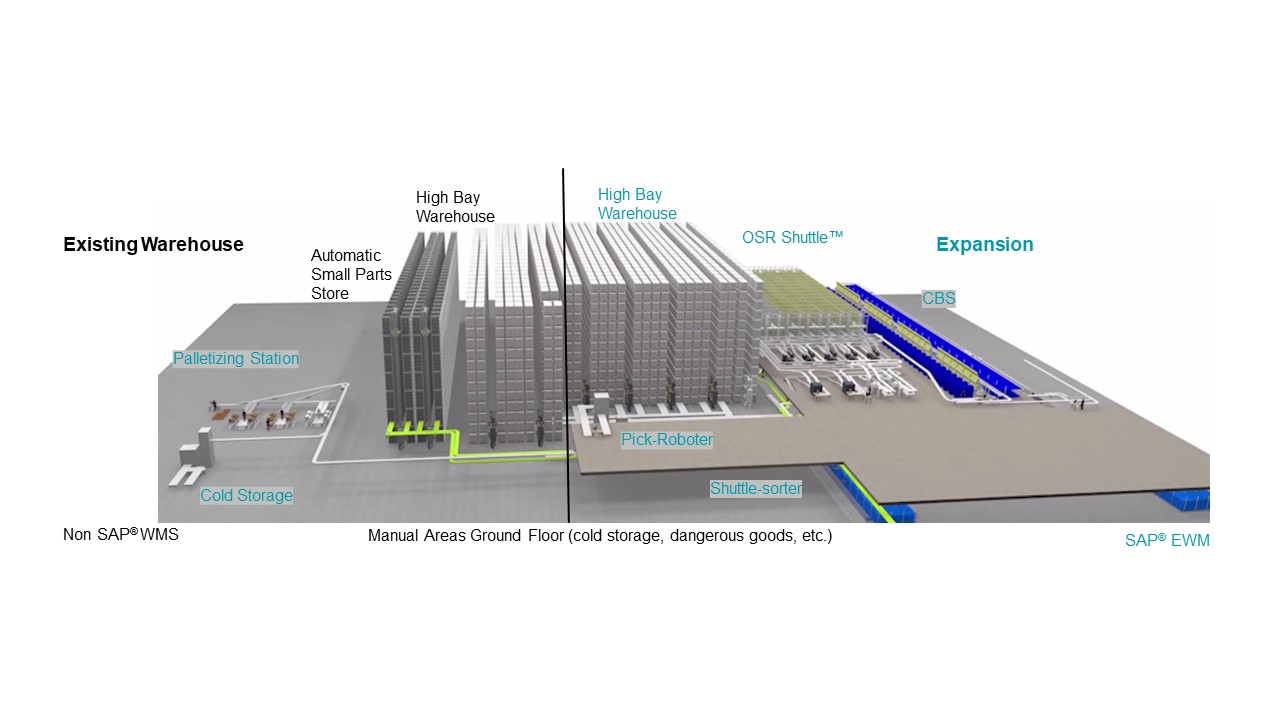

The idea behind VOLOGIN, which is short for VOIGT LOGISTIK INTEGRATION, is to expand the Niederbipp location by merging the distribution centers Neuendorf and Niederbipp in Switzerland. This merging process poses special intralogistical challenges because the subsidiaries were responsible for pre-wholesale and wholesale respectively. As an innovative concept, VOLOGIN unites these very different areas, pre-wholesale and wholesale, to create a seamless pharma value chain in a single logistics installation in one distribution center.

The solution focuses on the following:

The image shows the plan for merging the existing installation with the extension of the VOIGT subsidiary in Niederbipp, Switzerland. SAP® EWM by KNAPP controls the existing and new installation including all their processes and technologies to ensure the fulfillment of pre-wholesale and wholesale tasks in a single pharma value chain.

Do you want to learn more about logistics automation?

Get in touch with our experts today.

Translating the concept into a solution

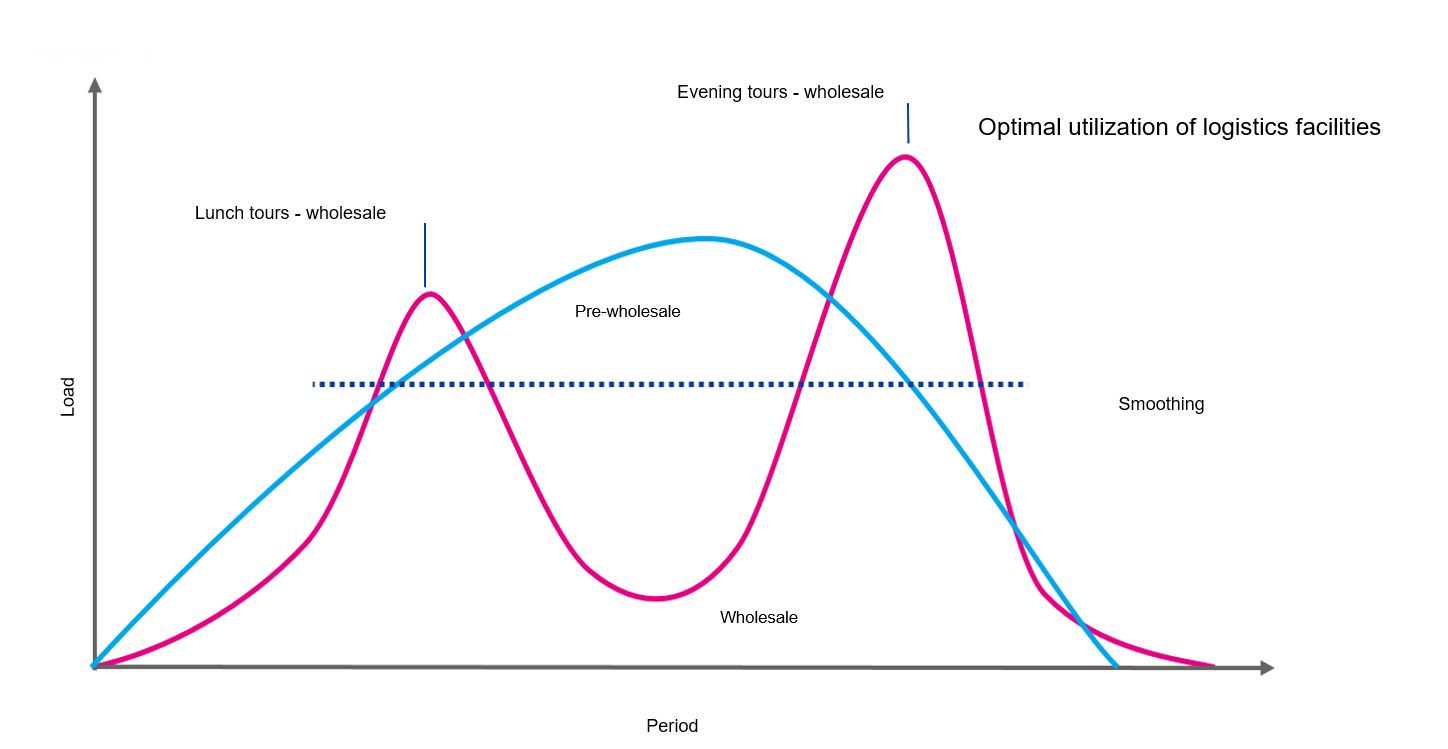

The logistics concept for the pharma value chain was designed based on an analysis of the two business fields to find out where they interface logistically and where potential operational synergies lie. The goal was to develop a solution that would accommodate the short-term peak periods in wholesale. While the workload for pre-wholesale is consistently distributed throughout the day, wholesale has two peak periods per day.

The logistical operations for the pre-wholesale business take place outside of these periods. This results in a consistently high and profitable use of the installation. SAP® EWM including MFS (Material Flow System) coordinates, controls and evenly distributes the workflows of both business areas within the warehouse throughout the day.

Since we provide the support to customers ourselves, we can respond flexibly to market and customer demands. The decision for SAP® EWM by KNAPP was a conscious one. We want to further develop and control the solution ourselves once the know-how transfer with KNAPP has taken place during implementation.

SAP® EWM by KNAPP–

the common denominator in the pharma value chain

Leading the way, the logistics software SAP® EWM by KNAPP silently controls the new innovative distribution center of VOIGT from behind the scenes. It’s the central control element, the place where all technologies and processes in the warehouse come together.

Here are some highlights of the software solution:

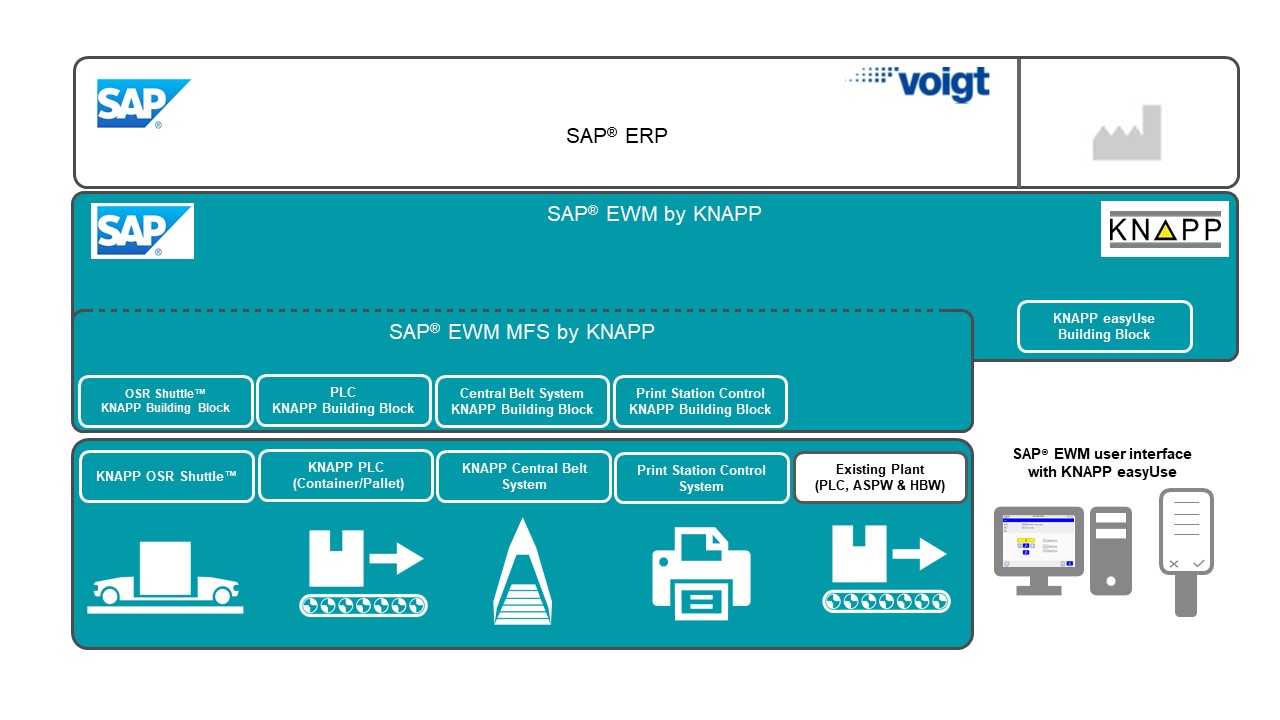

End-to-end SAP® solution with SAP® EWM including an MFS as the WMS and WCS

As a warehouse management and material flow control system, SAP® EWM by KNAPP depicts all processes from goods registration to goods-out in the RF-guided and automated areas. In detail, the solution covers:

KNAPP Building Blocks, our SAP® EWM software building blocks, close any gaps between the SAP® EWM standards and industry-specific requirements. For instance, order start could be optimized and adapted to wave planning.

In addition to the new warehouse automation provided by KNAPP for VOIGT’s extension, the control system of the existing third-party installation was also integrated in SAP® EWM. For this purpose, the non-SAP® WMS and WCS were replaced with SAP® EWM by KNAPP, thereby creating a harmonized end-to-end SAP® solution.

The image shows the plan for merging the existing installation with the extension of the VOIGT subsidiary in Niederbipp, Switzerland. SAP® EWM by KNAPP controls the existing and new installation including all their processes and technologies to ensure the fulfillment of pre-wholesale and wholesale tasks in a single pharma value chain.

Fully automatic supply of the Central Belt System using the OSR Shuttle™ Sorter system

The Central Belt System, a fully automatic station for highly dynamic picking, processes almost half of the hourly order lines. Thanks to shorter transit times, wholesale and pre-wholesale orders are processed efficiently with the individual items of an order being picked from the fast-mover autopicker and any requested large quantities directly from the overstock area adjacent to the autopicker. The autopicker is automatically supplied by an OSR Shuttle™ Sorter system. SAP® EWM by KNAPP integrates all processes in connection with the fast-mover autopicker, controls replenishment and ensures continuous lot tracking.

Integrated replenishment system for picking

While the dynamic stock is handled in the OSR Shuttle™ and OSR Shuttle™ Sorter systems, the overstock is located in the automated high-bay racking. To optimize stock movements, the pallets that are split during picking are routed to a repack table where they are separated and integrated. This way, overstock is already repacked and quickly available.

The automated calculation of range of storage in SAP® EWM ensures the OSR Shuttle™ is supplied from the required stock. The OSR Shuttle™ conveys the required containers to the Pick-it-Easy Health work stations and ensures that the workload is evenly distributed even during peak periods. Picking is carried out according to the goods-to-person principle.

Consolidation in the shipping area using SAP® EWM

An all-encompassing control concept with SAP® EWM integrates all processes related to consolidation in the automated and manual warehouse areas. As soon as the container arrives at the transfer station of the OSR Shuttle™ Sorter, it’s automatically read and stored in the Sorter according to predefined strategies. The OSR Shuttle™ Sorter knows the level and channel for container loading, which are calculated beforehand based on different criteria (route, container weight etc.) in an optimized way.

Thanks to this system, sorting routes for wholesale is much easier thanks to the timely separation of the routes for wholesale through buffering, fast transit time and guided loading. The system allows both the sequencing of shipping units and the processing of cartons and different handling units.

Flexibly equipped for the future

Thanks to the integrated, all-encompassing pharma value chain controlled by SAP® EWM by KNAPP, VOIGT can flexibly respond to changes in the regulations for the pharmaceutical sector, reduce logistics costs and has sufficient space to meet the demands of the rapidly growing pharma business and increasing number of customers.