We all know the pandemic brought about a real shift in shopping habits, driving big increases in online shopping and greater spending on groceries as restaurant dining plummeted. Online shopping now represents 10–15 % of grocery spend, according to Curt Avallone, Chief Business Officer at Takeoff Technologies, our partner in micro fulfillment. He says COVID-19 pushed online shopping adoption ahead by four to five years.

This new engagement model in grocery shopping is here to stay. In fact, research from Nielsen and the Food Marketing Institute says that consumer online grocery spending could reach $100 billion within the next three years.

But that doesn’t mean brick-and-mortar is going away any time soon. A recent Takeoff study found that, even in the midst of a pandemic, some 45 percent of respondents said they would prefer to shop in stores, with free pick up being a strong second choice.

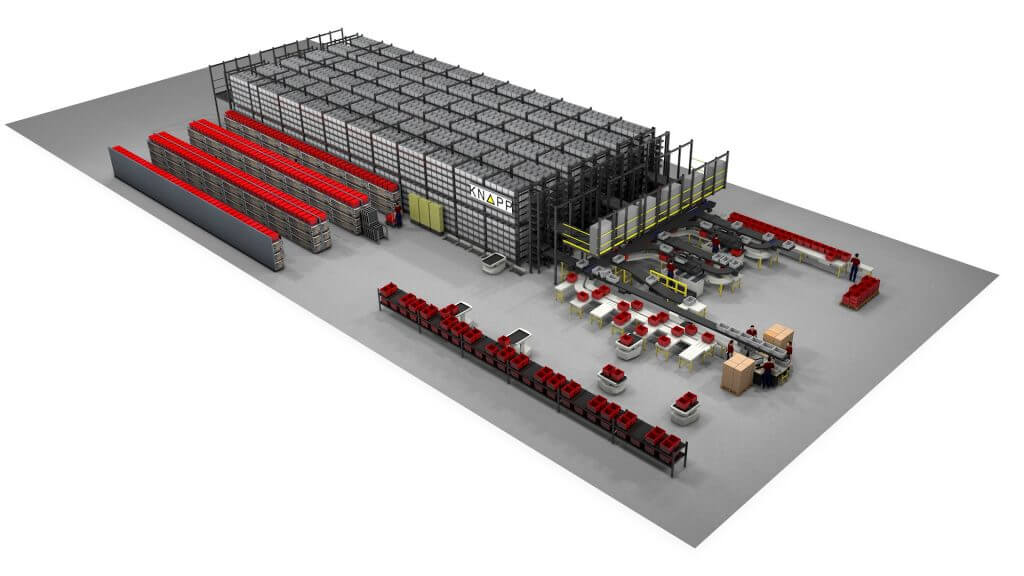

That strong second choice is why leading national retailers like Kroger, Walmart and Albertsons Safeway are investing in technology to offer customers optimal convenience and value. “The winners in eGrocery,” says Bill Stenger, KNAPP’s Director of Food Solutions, “Will be those that deliver a great and consistent customer experience the fastest.” The technology that’s making that happen: E-Grocer MFC, an automated micro fulfillment center.

Automated Micro Fulfillment Makes E-commerce Profitable

In our last MFC blog, experts shared their views on artificial intelligence, robotics and advanced mechatronics and how these technologies provide a path to e-commerce profitability for our customers such as food retailer Albertsons Safeway. Compared with other eGrocery options, E-Grocer MFC offers a host of advantages.

Placed in the back of the retailer’s store, automated MFCs:

- Can turn brick-and-mortar grocery stores into highly efficient online fulfillment hubs

- Bring together the location advantage of a physical store with productivity gains of over 5x compared to manual in-store picking.

- Enable stores to effectively support a wide range of SLA’s

- Can be installed quickly at a fraction of the time and cost that building a large, centralized warehouse would take.

- Can support multiple locations in a hub-and-spoke distribution model[1] to increase profitability and drive growth

We pioneered the MFC concept and are over four years ahead of the rest of the industry. To date, our partnership with Takeoff has countless MFCs in operation across the globe, processing over 45,000 digital orders weekly. With our model, total orders being processed more than double year-on-year.

Automated MFC performance is impressive, end-to-end they are filling orders five times faster than manual in-store picking programs. Early adopters continue to report 10-fold productivity improvement seeing picks at the automated stations every 5–6 seconds.

So, once automated MFCs are up and running, where’s the next level? In wolfpacks.

Breaking New Ground for Growth: Retail Alliances Create New Conveniences

Automated MFCs are making eGrocery profitable and can accelerate growth with their ability to deploy a hub and spoke strategy consisting of numerous stores within a region. These retailer alliances create new advantages.

- With two shifts of workers and a simple hub-and-spoke model, a single automated MFC can support efficient, high-volume online order and pickup programs: Up to 15 pickup locations at alliance partner stores

- Same-day, 30 minute pickup or 2 to 4 hour delivery service level agreements

“Automated MFCs have made it possible for grocery retailers to partner with local drugstores, convenience stores and quick-serve restaurants to better serve customers,” says Avallone. “The goal is twofold: to expand and enhance consumers’ ability to make online purchase pickups during everyday activities, and to guard against competitive threats.”

Alliance partners install automated lockers at their locations. At the MFC, online orders are retrieved robotically, placed in temperature-controlled totes, transported by automated shuttles and loaded onto dollies. The dollies are then loaded onto trucks, transported to the partner location and the totes are placed in the lockers. The totes are designed to maintain frozen, chilled and ambient product integrity for up to 24 hours.

The idea is gaining ground. An increasing number of major retail chains are forming wolfpacks across North America. In Canada, Loblaws Supermarkets currently operates more than 700 PC Express pickup locations at Tim Horton stores in grocery stores, pharmacies and transit stations across the country.

Automated MFCs Make eGrocery Profitable

Because the variable labor costs and initial capital investment in MFCs is comparatively low, grocers can now provide dominant players such as convenience stores and quick serve food retailers the ability to offer and price groceries competitively. Curt Avallone is not surprised. “We always knew that the manual fast-pick ware-rooms were more profitable than brick-and-mortar stores,” he says. “Now that we have the advantage of KNAPP automation technology, food retailers can reinvent themselves and reinvigorate growth with other experiences that their customers value.”

The wolfpack idea continues to build momentum. A large supermarket retailer is piloting an online grocery reward program tied to a convenience store partner in three markets. Test locations, which are pickup points for thousands of online grocery orders, are even outperforming pickup at the chain’s supermarket locations.

Enabled by KNAPP automation hardware and software, hyperlocal automated micro fulfillment centers are redefining what’s possible in the retail world.

Our E-Grocer MFC solution is constantly being refined, providing food retailers and their customers with countless new opportunities and services.

There is no doubt. The wolfpack is coming.

[1] The hub-and-spoke system can be compared to a spoked wheel. All of the spokes are connected to the hub in the middle. This link describes the structure of the logistic network. There are many depots available, all of which are spread across the board. The hub in the middle of the system forms the hub. Deliveries from the depots are bundled and then sent to the hub, the middle of the system.. The deliveries are arranged in the hub and sorted according to their destination. The deliveries are then distributed on trucks and driven to their destination. The deliveries are usually coordinated in such a way that the truck returns to a specific depot on the way back.

Further reading recommendations

Optimize intralogistics processes and increase performance using automation. What is the right level of automation for your operation? In this post, we present various levels from innovative manual warehouses up to fully automatic systems.

Quite often, shuttle storage systems are the heart of our customers’ logistics systems. But when the product life cycle is coming to an end, what are the options? We show you how a step-by-step retrofit plan works.

Autonomous mobile robots (AMRs) facilitate flexible, efficient transport processes. Whether deployed in manufacturing, food retail or in distribution logistics – their range of use is wide. Discover more about this future-oriented technology.

Additional Information

Would you like to learn more about intelligent e-commerce fulfillment or do you have specific questions? Contact us at sales.us@knapp.com.