Is this portrayal of a warehouse without humans just a utopian vision? Or could the increasing labor shortage soon make the dark warehouse a reality? We explain what role warehouse automation and robotics will play in the future, how the role of the human warehouse worker is changing and what our mission: zero touch has to do with all that.

First of all, what is a dark warehouse?

A dark warehouse is a fully automated warehouse that is operated with minimal to no human presence. What does this mean?

Modern technologies such as robots, automated storage and retrieval systems and artificial intelligence are used to manage and fulfill orders as well as other logistical functions. In a dark warehouse, a little human attention may be required for more complex processes such as goods receipt for packaging or labelling, but most of the system is automated.

Mitigating personnel shortages with full automation

Robots take over where humans reach their physical limits. Full automation is perfect for carrying out monotonous, repetitive and strenuous tasks.

Let’s be upfront: We are thoroughly convinced that the warehouse of the future is not a warehouse without humans, but rather one where humans work hand in hand with intelligent technologies to generate added value.

However, automation and digitalization do have their benefits, making it possible to mitigate the effects of personnel shortages, for instance. In short, people remain the key players in the warehouse, with technology as their reliable companion. The key question to ask, especially when dealing with labor shortages, is: What is the smartest way to deploy your most valu-able resource? Where can humans use the support from machines and when does it make sense to leave the entire process to robots?

In the course of an automation project, our design team works together with you to find out what processes make sense to automate and to create the right solution for your business.

Warehouse automation technologies

In the following, we show you which technologies could be used in a highly automated warehouse:

Robotic solutions for food retail: Relief for your heavy lifters

An average day for a food retail worker involves physically demanding tasks, such as manually assembling pallets. Robotic solutions such as RUNPICK, short for Robotic Universal Picker, and FAST Picking, Fully Automated Standard Tray Picking, were developed to do the heavy lifting for employees. RUNPICK processes and palletizes large handling units for brick and mortar retail fully automatically. FAST Picking combines multiple fully automatic technologies to create store pallets efficiently while saving space.

Relief from monotonous and repetitive tasks in fashion and e-commerce

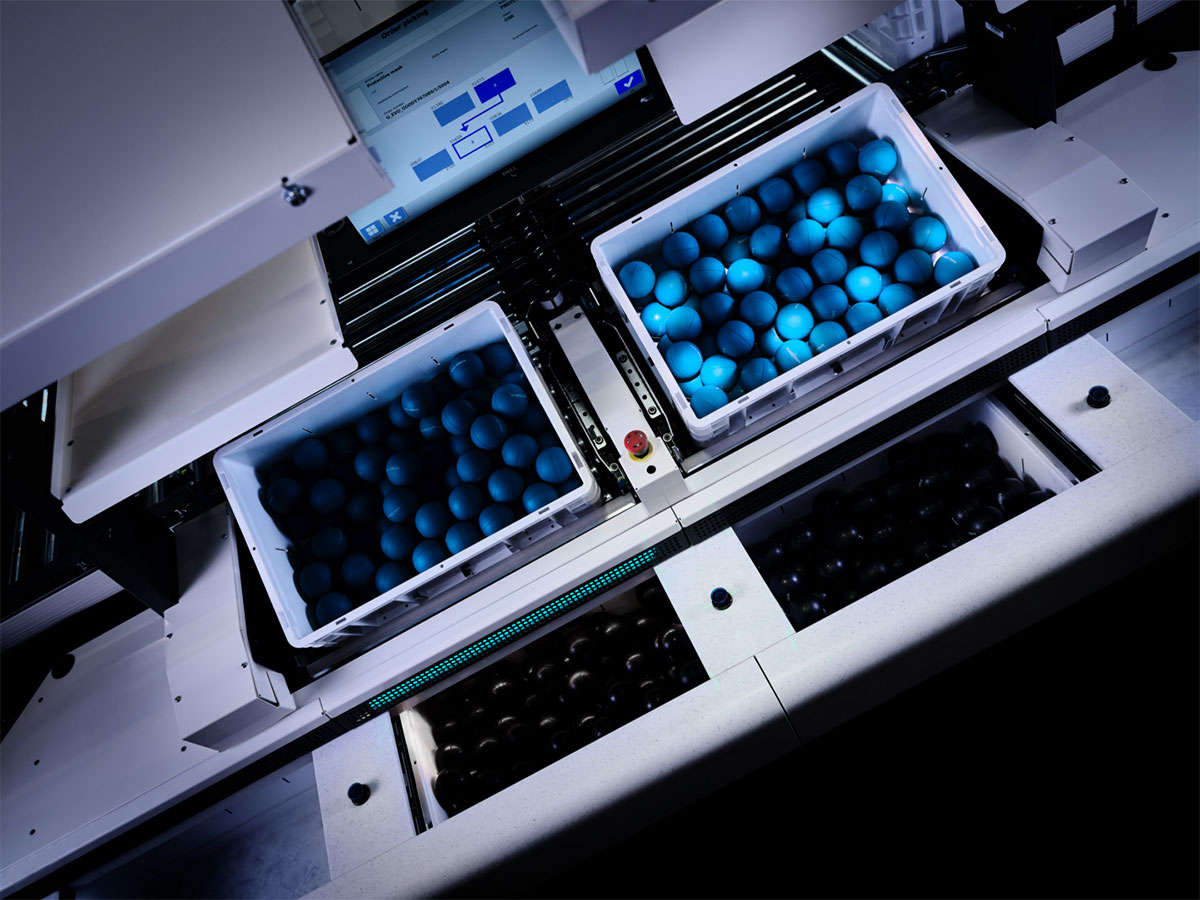

One of the most unpopular tasks in fashion and e-commerce warehouses is manually filling sorter pockets. Why? It’s incredibly monotonous and, frankly, quite boring work. Full automation using picking robots, such as our Pick-it-Easy Robot, is the smart approach to handling processes when personnel resources are tight, allowing the available employees to do tasks that are more meaningful.

Autonomous mobile robots also provide support for employees in warehouse-internal transport. Our automated guided vehicles, the Open Shuttles, connect different warehouse and production areas, complementing or even replacing forklifts.

Humans and robots team up: Support personnel with semi-automation

When dealing with personnel shortages, don’t just worry about the employees you’re missing – think about the team you already have! Intelligent technologies are a great way to keep employees at your company and to assign them more meaningful tasks.

Picking at the ergonomic work stations: On your mark. Get set. Go!

Picking orders is a central process in distribution centers. Our Pick-it-Easy goods-to-person work stations form the intelligent interface between people and automation technology. The work stations are ergonomically designed and optimize manual processes, such as picking, returns processing, repacking, inventory, merging or value-added services. This takes the physical strain off employees and makes achieving top performance and optimal quality in order processing a breeze.

Smart work stations for assembly

It’s becoming increasingly difficult for manufacturers to find qualified personnel, so the employees they do find should be trained and able to work as quickly as possible, which increases both productivity and employee satisfaction.

Smart work stations help employees learn their new job as quickly as possible thanks to simple, step-by-step workflows, many graphical elements and color-coding. One such smart work station is our vision smartdesk. It digitalizes manual processes and uses graphics to provide work instructions. New employees are productive immediately because the system guides them through the work process step by step and provides correction if necessary.

What’s to come: Humans in a digitalized, highly automated world

Even though robots and artificial intelligence are transforming production and distribution processes, humans have and will continue to have the most important role in logistics processes. The only thing that’s changing is what they do.

Warehouse employees are becoming smart workers and taking over complex programming tasks or stepping into new duties as analysts or maintenance technicians.

We are also witnessing an increased demand for creativity in industry. Now more than ever, people are needed to drive creative innovation and make analytic decisions. Of course, intelligent technology also assists people in these areas. For example, predictive software solutions such as KiSoft Analytics provide warehouse operators with the pre-analyzed information they need to guide their business at all times. Intelligent software supports more than just your daily business; it also handles maintenance and servicing of automated systems. What’s important here is finding just the right balance between normal operations and the necessary servicing. The intelligent software KiSoft CMMS makes data-driven maintenance decisions to ensure the system runs at its best.

As you can see, the warehouse of the future is far from bleak. It’s full of possibilities!

Further reading recommendations

The requirements for freezer warehouses are complex. A high degree of automation is an important ingredient for success. Find out more about the challenges of operating a freezer warehouse, what makes it special and different logistical approaches.

Flow meter manufacturer Digmesa automates production using an Open Shuttle. Learn more about the flexible solution in an interview with managing directors of the Digmesa Group.