Logistics automation in warehouse and production at VOLA enables great customer experience

VOLA A/S, with headquarters in Horsens in eastern Jutland, Denmark, has been one of the world’s most successful manufacturers of taps and shower mixers for more than 50 years – with long-lasting form and function at the core of every one of their designs. In an industry characterized by mass production and constant reduction of costs, VOLA have always trodden a different path, insisting on customer order-driven manufacturing and worldwide distribution from its only warehouse located directly next to their factory in Denmark. We asked Chief Operations Officer Peder Nygaard to explain how KNAPP’s flexible automation solution helps VOLA create the perfect customer experience – every single time.

150,000 item numbers in the range

Logistics solution consisting of KiSoft, OSR Shuttle™ Evo, Streamline and Pick-it-Easy Flex

Sophisticated design, customer experience and logistics are top priority

In 1961, Verner Overgaard, owner of VOLA A/S, approached world-famous architect and designer Arne Jacobsen, introducing his at the time revolutionary idea of a bathroom mixer where all the mechanical parts are hidden, leaving only the spout and handles as an architectural expression. Mr. Jacobsen combined the idea with his functional approach to design, earning a place in design history. Today, VOLA offers a wide range of premium kitchen and bathroom equipment, implementing prestigious projects and delivering to designconscious private customers all over the world. The company is still owned by the Overgaard family and production continues to take place in Denmark exclusively. Peder Nygaard is also part of VOLA’s success story. He has been involved in the logistics aspect of the business for 22 years.

Today, he is responsible for the entire chain, from product development and manufacturing to warehouse management and global distribution. “VOLA is one of those companies you can see yourself being a part of for a long time. We all have the feeling that we are carrying on a significant legacy. The only downside is that I can hardly blame anyone else for mistakes in our logistics except for me”, says Mr. Nygaard with a laugh.

The entire production is customer order-driven: A tap is made only after the customer has ordered. We sell the entire stock twice a week. This means that the processes in the warehouse must run extremely smoothly and fast. Not only our products, but we too have to be top of the line for our customers, in everything we do.

A supply chain shorter than most

VOLA’s supply chain is, as Mr. Nygaard describes it, extremely short. The company’s only warehouse is located directly next to the factory. Both project and consumer orders are picked and packed in the warehouse. The products are shipped directly to the customer, without passing through external distribution centers or retail warehouses. “This chain of supply poses special challenges, however,” says Mr. Nygaard.

With over 150,000 item numbers in their range, VOLA faces a tremendous challenge with regard to inventory management. For this reason, in 2019, they decided to invest in an advanced automation solution to facilitate their picking and packing processes.

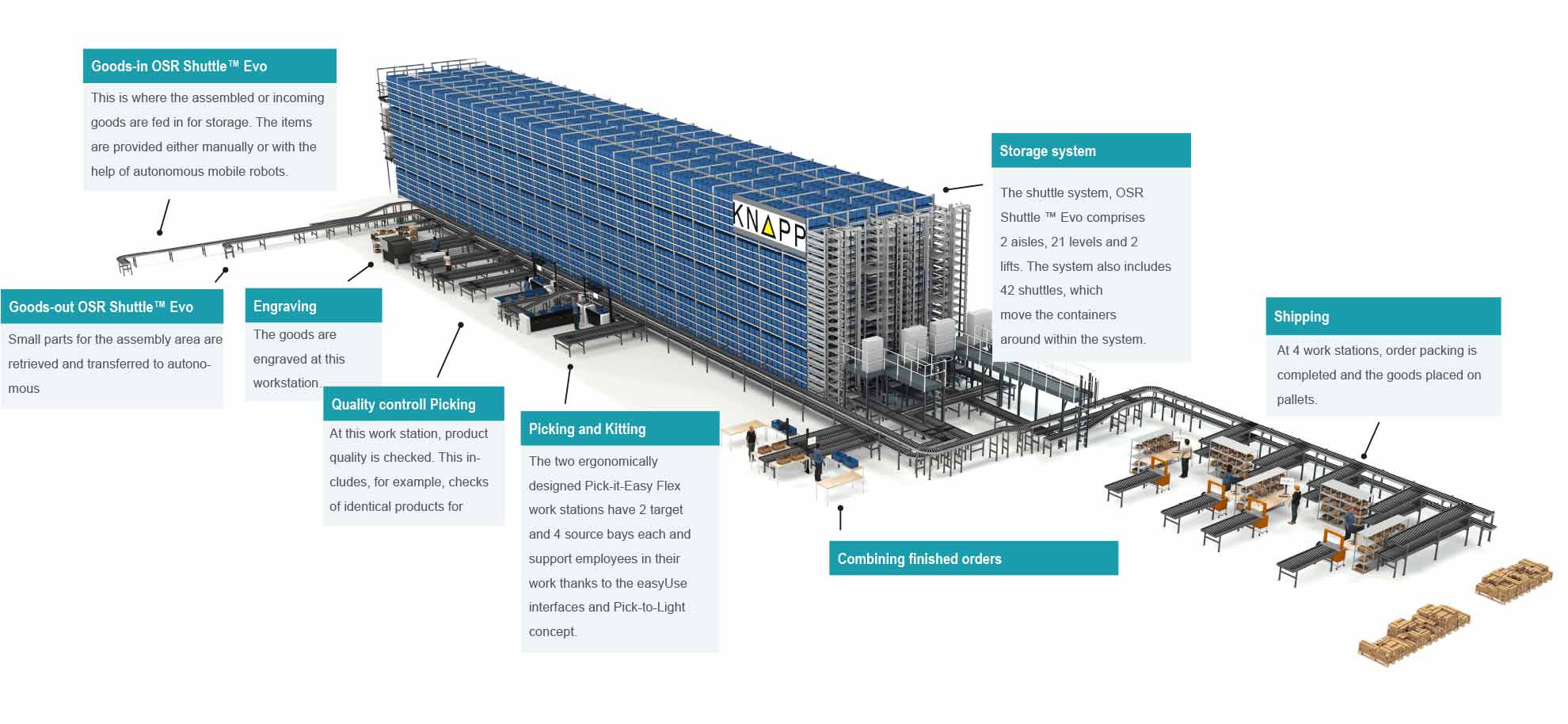

VOLA chose KNAPP from a selection of suppliers, opting for the automatic OSR Shuttle™ Evo storage and picking system, Pick-it-Easy Flex work stations and conveyors of the Streamline series. VOLA’s ultimate goal in automating their processes was to strengthen their position on the high-end market and create added value for customers in the delivery process. Thanks to KNAPP’s systems, the company is, for instance, now able to efficiently pack the taps for a large hotel project according to room and floor, making work at the construction site a lot easier.

Flexible solution with OSR Shuttle™ Evo, Streamline conveyor and Pick-it-Easy-Flex

- Application: Automated small parts warehouse for inhouse production and assembly supply

- Storage system: OSR Shuttle™ Evo 1D for up to quadruple-deep storage of different container types (42 shuttles, 2 lifts, 2 aisles, 21 levels)

- Performance: 800 douple cycles per hour

- Storage locations: 16,800 for containers sized 650*400*250 mm (25.59*15.75*9.84 in) (double-deep) as well as for containers sized 400*300*250 mm (15.75*11.81*9.84 in) (quadruple-deep) with a maximum weight of 15 kg (33.07 lb)

- Workstations: 2 Pick-it-Easy Flex, additional manual stations as well as 5 packing stations for shipping

- Special features: Various processes combined in the OSR Shuttle™ Evo: picking, buffering, sequenced assembly supply, buffering, sequenced retrieval, shipping

- Software: KNAPP KiSoft One with web services interface to customer system Dynamics AX, KiSoft SCADA visualization

Every delivery must be absolutely perfect. There are many famous architects who exclusively use our taps in all their projects. If we fail once, we might lose business for many years to come. KNAPP’s solutions help us deliver high quality reliably.

Do you want to learn more about logistics automation?

Get in touch with our experts today.

The process

Goods received by AX are transmitted from the host system to KiSoft One via a KNAPP interface.

The OSR Shuttle™ Evo handles various processes, including goods-in, storage, picking and buffering of semi-finished parts, sequenced supply of assembly, buffering of finished parts, and sequenced retrieval for shipping.

The picking process takes place at the Pick-it-Easy Flex workstations where employees are guided through the respective process following a Pick-to-Light procedure and using the easyUse user Interface. Picking includes the picking of spare parts and parts for production as well as the direct supply of assembly areas and the kanban racks located there.

After picking, the semi-finished goods are buffered in the OSR Shuttle™ Evo and then transported back to the assembly workstation in the right sequence.

The finished goods are buffered in the OSR Shuttle™ Evo until the order is ready for shipping. When the time has come, the goods are retrieved in the right sequence and provided in the shipping area.

Increased complexity due to the pandemic

In January 2020, the new automation solution was put into operation. Conversely, the timing turned out to be spot on. While the project market has plummeted since the COVID-19 outbreak, orders for taps from private customers have soared, intensifying the picking and packing processes even more. In addition, the demand for colored taps has grown as some interior design trends have continued. With 35 tap colors on offer at VOLA, the number of possible component combinations is extremely high.

Room for expansion

And what about the future? The warehouse in Horsens was constructed with growth in mind, there is room for another OSR Shuttle™ Evo aisle. What’s more, Mr. Nygaard does not rule out further investments, although he hopes that it will be a few years before they grow out of the solution.

Do you want to learn more about logistics automation?

Get in touch with our experts today.