Omni-channel fulfillment:

Parfums Christian Dior relies on exclusive logistics solution

Parfums Christian Dior stands for exclusive scents and luxurious cosmetics. The company, part of the well-known LVMH Group, produces their perfumes and cosmetic products in the Orléans region of France, in Saint Jean de Braye. Here, a state-of-the-art omni-channel fulfillment center has been in operation since 2018, with smart robots handling a large portion of the work.

8 percent stock growth

per year

64,000 order lines

per day

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationParfums Christian Dior relies on omni-channel distribution

Products of the brands Parfums Christian Dior, Benefit and Forever are distributed worldwide from the omni-channel DC at the headquarters in Saint Jean de Braye in France. The central DC at headquarters supplies the regional DCs in the USA, Asia and the Middle East, as well as all points of sale in Europe. All purchases made through the Dior.com website are also fulfilled from this site. The sophisticated omni-channel solution is highly automated, bringing performance and efficiency to the logistics processes. The new solution furthermore optimizes the workflow for warehouse workers and creates capacity for further growth. Join us on a tour of the warehouse, where Logistics Manager Oliver Sorbe and Sales Director of KNAPP France, Brice Gaujard, give their insights on the project.

We chose KNAPP because from the start it simply felt right – the team was very much in tune with our specific requirements. They really understood our complex processes and created a highly efficient automation solution to meet our needs.

The omni-channel fulfillment center in Saint Jean de Braye plays an important role in the Parfums Christian Dior distribution network, handling the following tasks:

Supplying the regional DCs

Supplying shops

Fulfilling online orders

Intelligent automation solution for the special requirements of the cosmetics industry

In designing the solution for the Parfums Christian Dior omni-channel fulfillment center, the focus was on the following goals and processes:

- Omni-channel fulfillment: Delivery to regional warehouses and points of sale

- Speed: Next day delivery

- Performance and gentle handling: 64,000 order lines per day and 14,600 full cases per day

- Highest quality: Gentle handling and zero error strategy

- Automated but still flexible: Especially for palletizing and depalletizing

- Optimum ergonomics: Ideal work sequences for employees, minimizes walking and heavy lifting.

- Shifts reduced to 2: 5 day operation, night shift omitted

- Capacity for growth: Scalable warehouse system design; 8 percent stock growth per year

- Optimal use of space: Solution integrated into the existing system

- Handling full cases and single items, handling different carton sizes, direct storage of cartons

- Buffering orders and creating perfect sequences for dispatch and palletizing and automatic labeling

- Automatic depalletizing and palletizing: Assembling mixed pallets

When designing omni-channel solutions, it is crucial to keep in mind that the goods flows must not affect each other. At Parfums Christian Dior, there are two flows of goods – one for full cases and one for single item picking. The goal was to transform the complex requirements of each into a unique, simple and efficient solution.

Brice Gaujard

Director Sales KNAPP France

Pick-it-Easy Robots

central warehouse system

ergonomic goods-to-person workstations

lines per hour

intelligent software solution

shift operation

Goods in: Depalletizing goods automatically

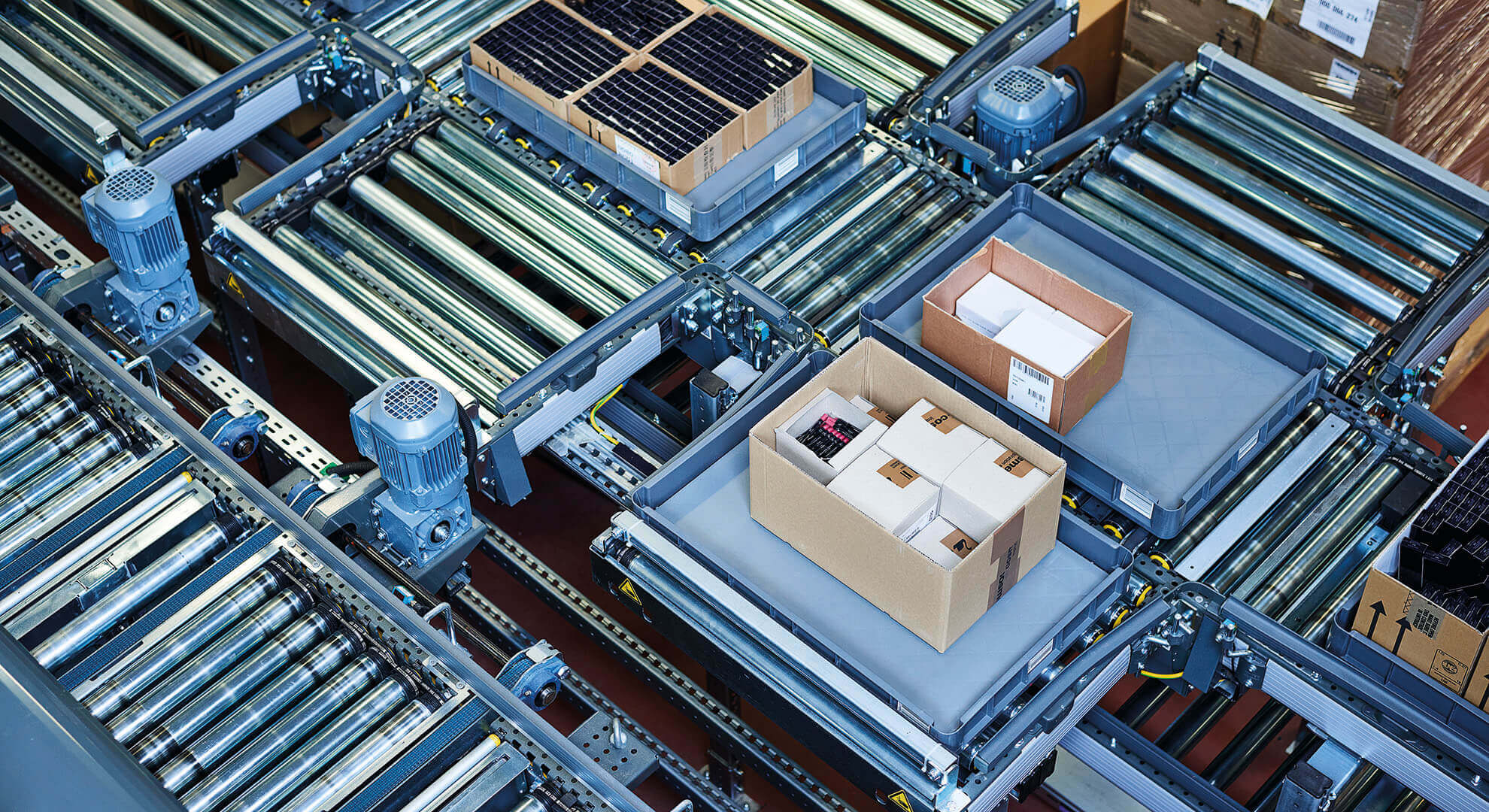

Full cases used to be depalletized manually. Today, special robots handle these strenuous tasks, taking the load off the employees. The robots depalletize full cases with goods from mixed and unmixed pallets. In the same step, the weight and dimensions of each carton are recorded automatically and transmitted to the warehouse management system. This creates the basis for transparent, error-free processes.

- Fully-automatic depalletizing of mixed and unmixed pallets

- Storage density increased with small cartons arranged on trays.

- Image recognition technology automatically captures master data

- Manual goods-in process for special goods

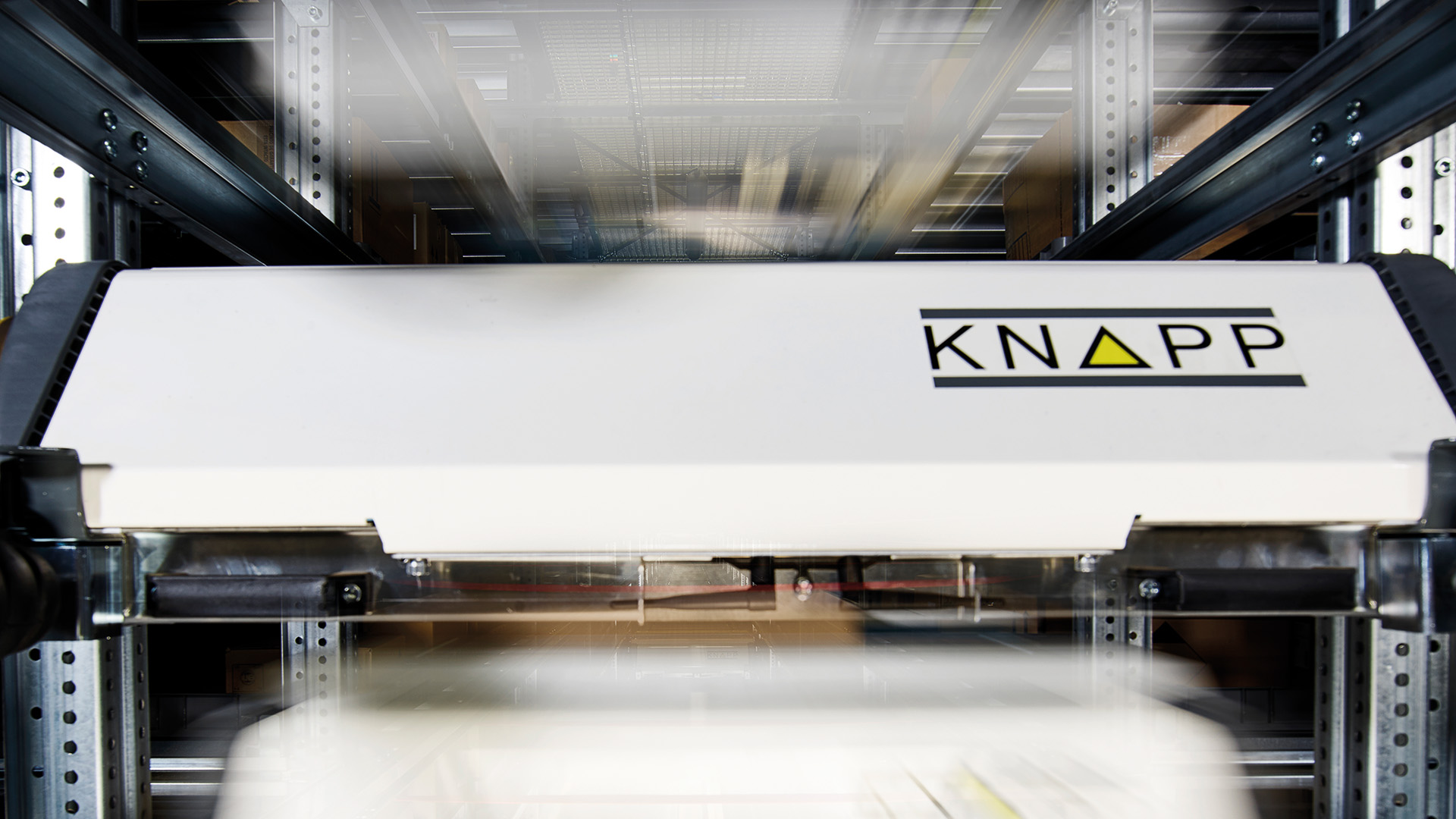

Warehouse system: Growth capacity planned from the get-go

The OSR Shuttle automated warehouse system is the very heart of omni-channel fulfillment. In it, you can centrally store full cases for delivery to shops and open cases used for picking single-item e-com orders. Thanks to intelligent software, every item can be accessed and stock is always in view. Parfums Christian Dior expects a growth in stock (SKUs) of 8 percent per year. The shuttle system offers sufficient capacity for this growth and can also be expanded by 3 rack line systems. One particularly efficient feature is buffering orders in the OSR Shuttle™ prior to dispatch. As a result, resources are used much more efficiently.

- Entire range of goods stored centrally

- Complete transparency and immediate access to every item

- Tray storage and direct storage of cartons

- Buffering orders for efficient use of resources

- Optimal storage density thanks to double-deep storage

- Future-proof: Scalable storage system for stock growth

One touch picking: ideal for cosmetics

At the 8 goods-to-person workstations of the Pick-it-Easy series, employees carry out manual picking. These workstations are specially designed for the small, lightweight and high-quality cosmetics of Parfums Christian Dior. Ergonomics and efficiency are central to the process, in which the target and source cartons are automatically fed in and presented at an ergonomic height. The employee picks the goods directly into the target carton so that each item is only touched once. All processes are supported by the software, with each step in the work process displayed on a touch screen. This ensures not only a continuous workload, but also the highest efficiency, flexibility and quality in order fulfillment.

- Goods-to-person: Optimized single item picking

- Pick-it-Easy: Ergonomic, efficient and error-free working

- All items are accessible: Each work station can access every item from the OSR Shuttle™

- Intelligent software-guided processes using touch screen

For me, one of the major successes in this project was how the manual picking procedure was optimized. Our employees now work hand-in-hand with ultramodern automation technology. All the work processes are ergonomic and software guidance reduces errors to a minimum.

Dispatch preparation: Automatic labeling and perfect sequences

Labeling full cases is an important process for the cosmetics retail sector. At Parfums Christian Dior, this process is now efficiently automated: The correct label is applied to each carton as it passes by. Then the cartons are automatically conveyed in the right sequence to dispatch for palletizing.

- Fully-automatic labeling of full cases

- Perfect sequence created fully-automatically

- Efficient dispatch preparation

Assembling mixed pallets is an important process in cosmetics retail. When done by hand, it’s time-consuming and errors are common. Robots, in combination with our intelligent packing arrangement calculation software, provide significant advantages here. Our solutions have efficiently automated this process, which is crucial for Parfums Christian Dior, boosting quality and performance for the long term.

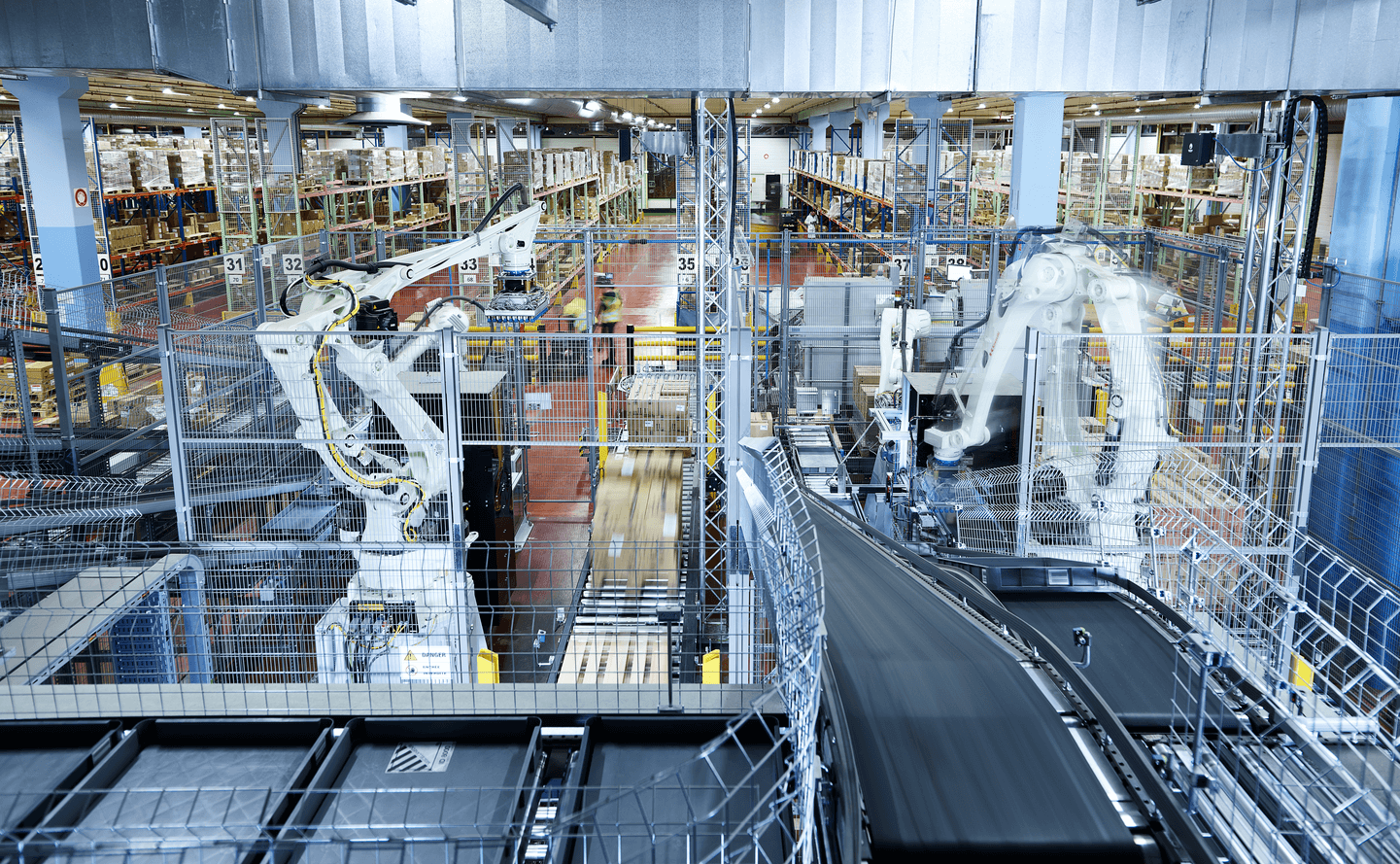

The perfect pallet arrangement in dispatch: Robots play Tetris

The three robots in dispatch efficiently palletize most of the orders. This increases the efficiency in dispatch, while at the same time, with the robots doing the heavy work, the employees in dispatch have to palletize just a small proportion of goods manually. The packing arrangement for the pallet is determined by intelligent software – KiSoft Pack Master. Packing requirements such as stack heavy items before light ones can be fulfilled automatically. The robots place each carton in its predetermined location, wrap the pallets and supply them for dispatch.

- Automatic palletizing

- Assembling mixed pallets

- Efficient automatic dispatch processes

- Robots reduce physical strain on employees in dispatch

- Stable pallets thanks to calculated packing arrangement

This project turned out to be quite an adventure for me. We worked closely with the KNAPP team to realize the project successfully within 18 months. The key to our success was open communication and professional, cordial collaboration in every project phase.